LATI flame-retardant compounds are designed to minimize the risk of fire in high-risk applications such as electrical, electronic, household appliances, e-mobility, and railway transport.

Our materials are optimized to successfully pass rigorous flame resistance tests, including UL94, GWIT, GWFI, and GWEPT tests, and comply with internationally recognized industry standards such as IEC60335 and EN45545.

We offer reliable flame-retardant materials over time, with reduced environmental impact:

- Traditional halogen-based solutions, reinforced and non-reinforced, for maximum flame performance;

- Materials loaded with red phosphorus and intumescent systems for high resistance to creeping currents;

- Halogen-free and red phosphorus-free products, for minimal environmental impact.

We also offer many other solutions designed to tackle market challenges in terms of

- miniaturization and thin walls;

- high voltages present and therefore resistance to creeping currents;

- increased operating temperature.

LATI self-extinguishing solutions are available on every thermoplastic polymer, including from recycled raw materials.

Winning Characteristics

Maximum Fire Resistance

Environmental Sustainability

International Certifications

Application Versatility

Long-term Reliability

Brochures and Catalogs

LATI PRODUCTS GUIDE Engineering Thermoplastics - Flame Retardant - High Performance

Discover Self-Extinguishing Materials

Explore the LATI materials database and discover all the technical characteristics of our flame-retardant materials.

Discover UL Certified Materials

Explore the LATI materials database and discover all UL certified grades and their technical characteristics.

Sectors and Applications

Learn more

F.A.Q.

Frequently Asked Questions

All common plastics burn and, by releasing large amounts of heat, can promote fire propagation. There are intrinsically flame-retardant polymers, such as PPS and PEEK, while for others it is necessary to create formulations that prevent or slow down the combustion reaction. LATI offers a wide range of fire-resistant compounds developed on different base resins and different flame-retardant systems, capable of meeting the most diverse project requirements.

First, the base polymer must be selected according to the thermal, chemical, and mechanical requirements of the application. Then, it is verified which flame-retardant system allows obtaining the flame and glow wire resistance required by the safety requirements imposed by the field of use. LATI quality control and designated certifying bodies verify the suitability of the materials for the expected performance. Given the complexity of the scenarios that arise, it is always advisable to rely on the guidance of industry experts.

The certifying body UL has created the UL94 standard which establishes the flammability grade of a plastic material and the consequent dripping of molten and ignited polymer. It then establishes the resistance to direct fire and the ability to propagate the fire to the surrounding environment by assigning a safety level based on the thickness of the tested artifact. This rating ranges from HB, meaning flammable, to V0, meaning flame-retardant and not capable of causing dangerous dripping. LATI offers V0 certified materials up to thicknesses of 0.4 mm

In addition to resistance to free flame, it is often necessary to verify how materials behave when in contact with an overheated metal, as occurs in the case of an electrical short circuit. Glow wire resistance tests (or glow wire test, GWT) evaluate precisely the maximum ignition temperature of the polymer, the glow time, and the extinction time. These pieces of information are vital especially in the case of unattended applications, such as in appliances. LATI offers compounds with maximum certified resistance for GWIT, GWFI, and GWEIPT tests.

Many flame-retardant additives consist of mixtures of extremely safe and high-performance primary and synergistic retardants, but their formulation may contain halogens, red phosphorus, and other substances of concern at the level of environmental and human health safety. Although all LATI formulations are constantly updated to the highest level of safety imposed by current regulations, the efforts of R&D are aimed at creating increasingly less problematic materials.

In addition to traditional intumescent formulations based on PP, high-performance flame-retardant solutions developed on PA6, PA66, PBT, PPA, and PA9T bases are available, also reinforced, free of halogens and red phosphorus. These are the HF1 grades, now also created starting from recycled polymers. HF1 products allow maximum flame retardancy, resistance to creeping currents of 600V, GWIT values of 775°C or higher. Consult our materials database.

Except for intrinsically flame-retardant polymers, such as PPS, PPSU, and PEEK, LATI flame-retardant compounds are not suitable for contact with drinking water or food, nor are they suitable for the manufacture of toys or for medical applications intended for contact with the human body.

Compounds containing flame-retardant additives must be handled and processed strictly according to the instructions in the safety data sheet and the relevant technical sheet. In particular, it is imperative to respect drying times; extreme molding conditions, e.g., temperatures, thermomechanical stresses, and residence times, geometries with too thin walls or too small injection points, should be avoided. Attention should also be paid to hot runners and scrap recovery. The composition of the material cannot be altered in any way if certified, e.g., by introducing color masterbatch.

Molding flame-retardant compounds requires experience and attention. The additives present can lead to the formation of corrosive chemical species for molds and plasticizing cylinders; this phenomenon can be slowed down by strictly following the guidelines in the technical sheet. Phenomena such as sludge accumulation in molds, embrittlement, and aesthetic defects on molded parts can also be eliminated by adjusting drying and molding conditions.

The possible degradation of flame-retardant additives can damage the equipment and produce artifacts with inadequate performance.

Although theoretically possible, the recovery of flame-retardant compounds must be approached consciously, knowing that reprocessed materials tend to gradually lose mechanical and flame-retardant properties. Generally, it is possible to dilute 15-25% of homogeneous regrind material in the same virgin compound. For certified materials, the instructions in the UL yellow card must be followed.

To support the development of applications with lower environmental impact, LATI has created the LATIECO range of compounds obtained with recycled raw materials. Among these are certified flame-retardant grades developed on PA6 and PA66, whose performance is perfectly in line with analogous products from fossil sources.

CASE STUDY, WEBINAR & MORE

Discover the Latest News about our Flame-Retardant Materials

Webinar – Advanced Plastic Materials for E-Mobility

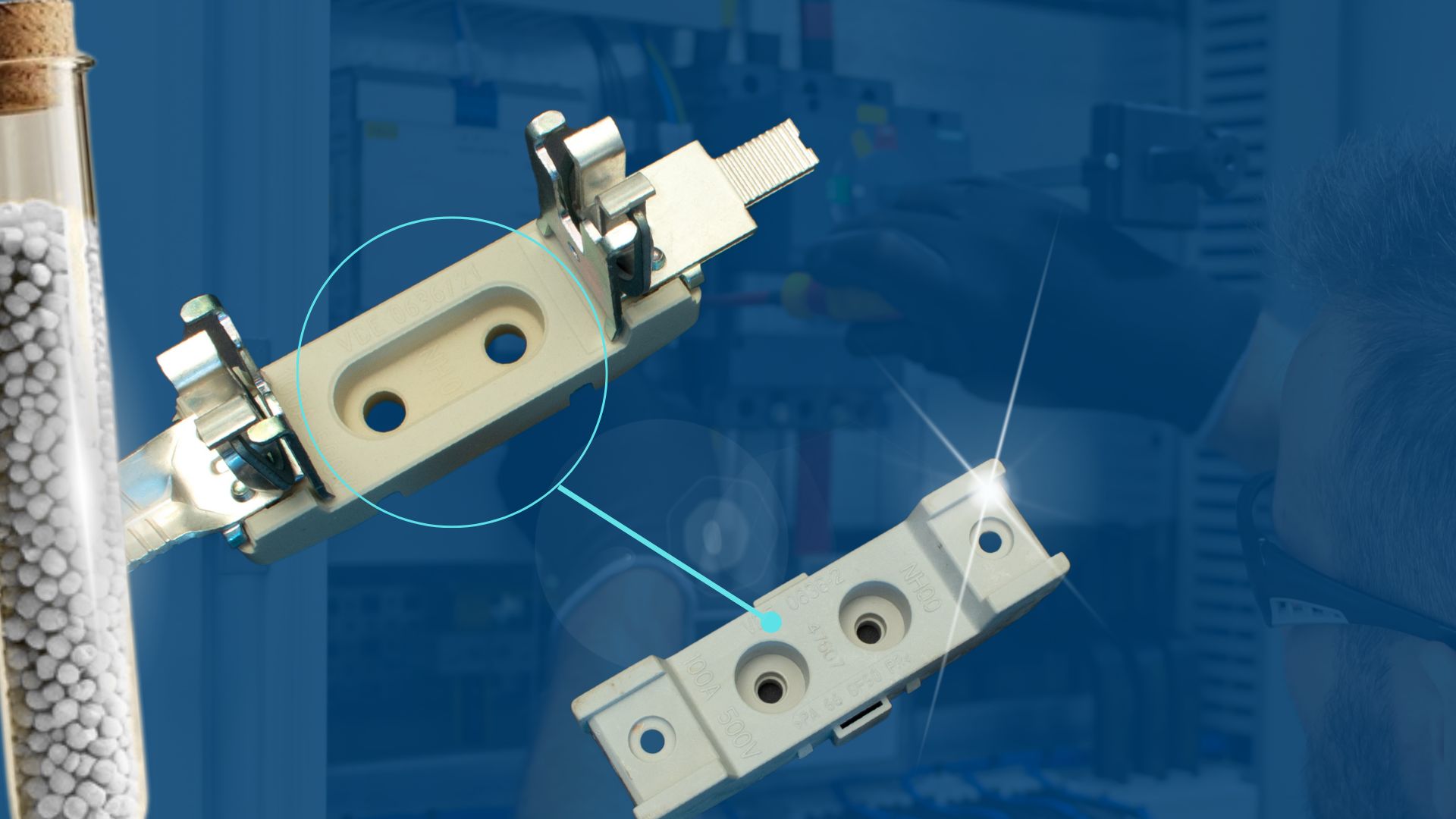

How to Choose the Right Material for Safety in Household Appliances

LATI Obtains BIS Certification for a Flame-Retardant Compound for the Indian Market

The Future of Flame-Retardant Materials: Sustainability, Safety, and Multifunctionality

LATI in Renault 2025 Panel: Thermoplastic Compounds for Electric Mobility

LATI confirms its leading role in the transition towards sustainable mobility, with high-performance thermoplastics included in Renault Group’s A-PMR 2025 panel.

Flame Retardant Additives: What They are and why They Really Matter

From halogenated compounds to intumescent systems, an overview of the ingredients that make polymers safe, considering performance, regulations, and sustainability.