Feasibility Analysis and Co-Design through Numerical Simulation

LATI offers its clients comprehensive support based on the use of specialized expertise and state-of-the-art simulation software to safely assess project feasibility, solve molding issues, and verify long-term reliability. Simulations can preemptively identify performance, molding, and dimensional stability issues, allowing for geometry and mold corrections, thus reducing development time and production costs.

LATI is always in synergy with the client to improve product and process performance.

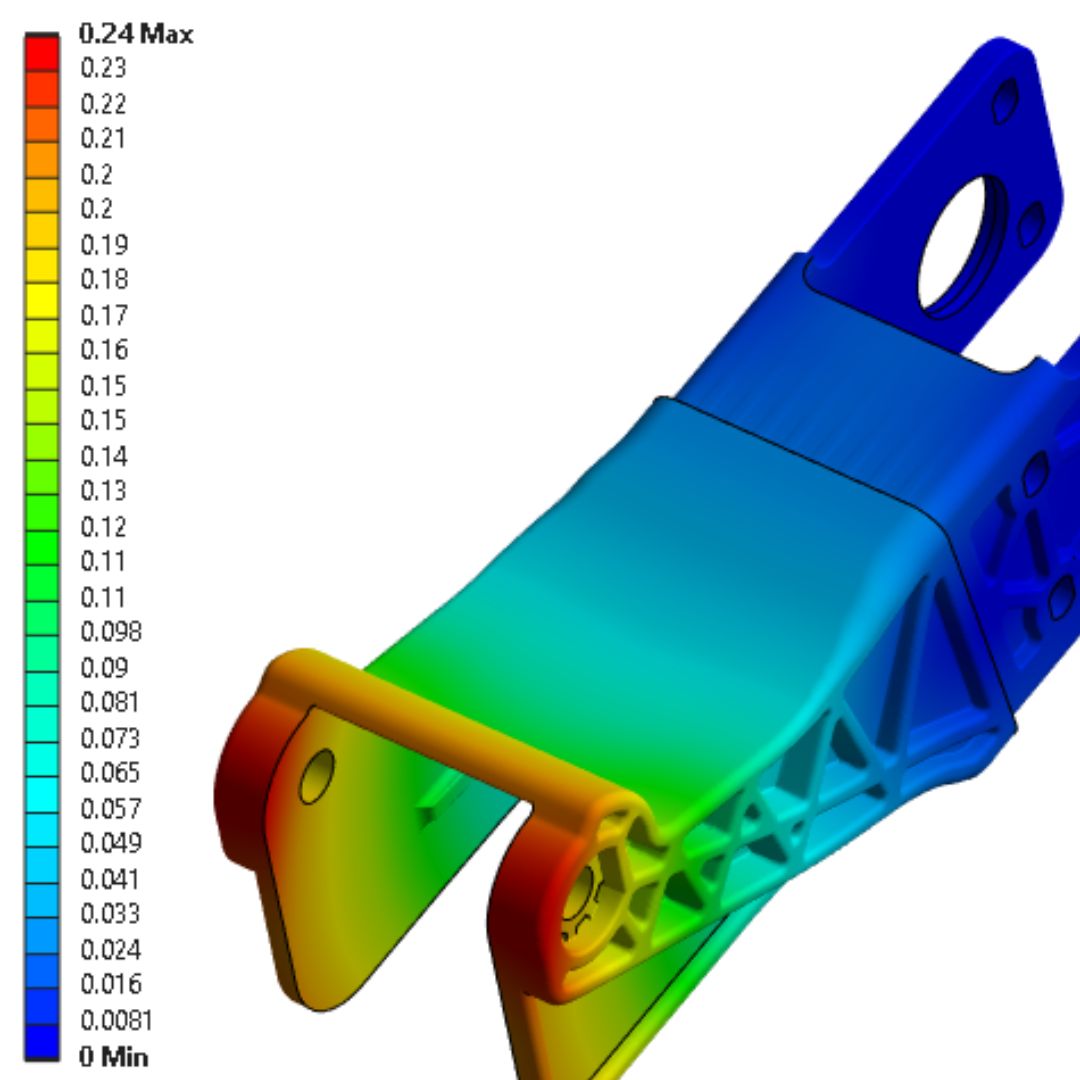

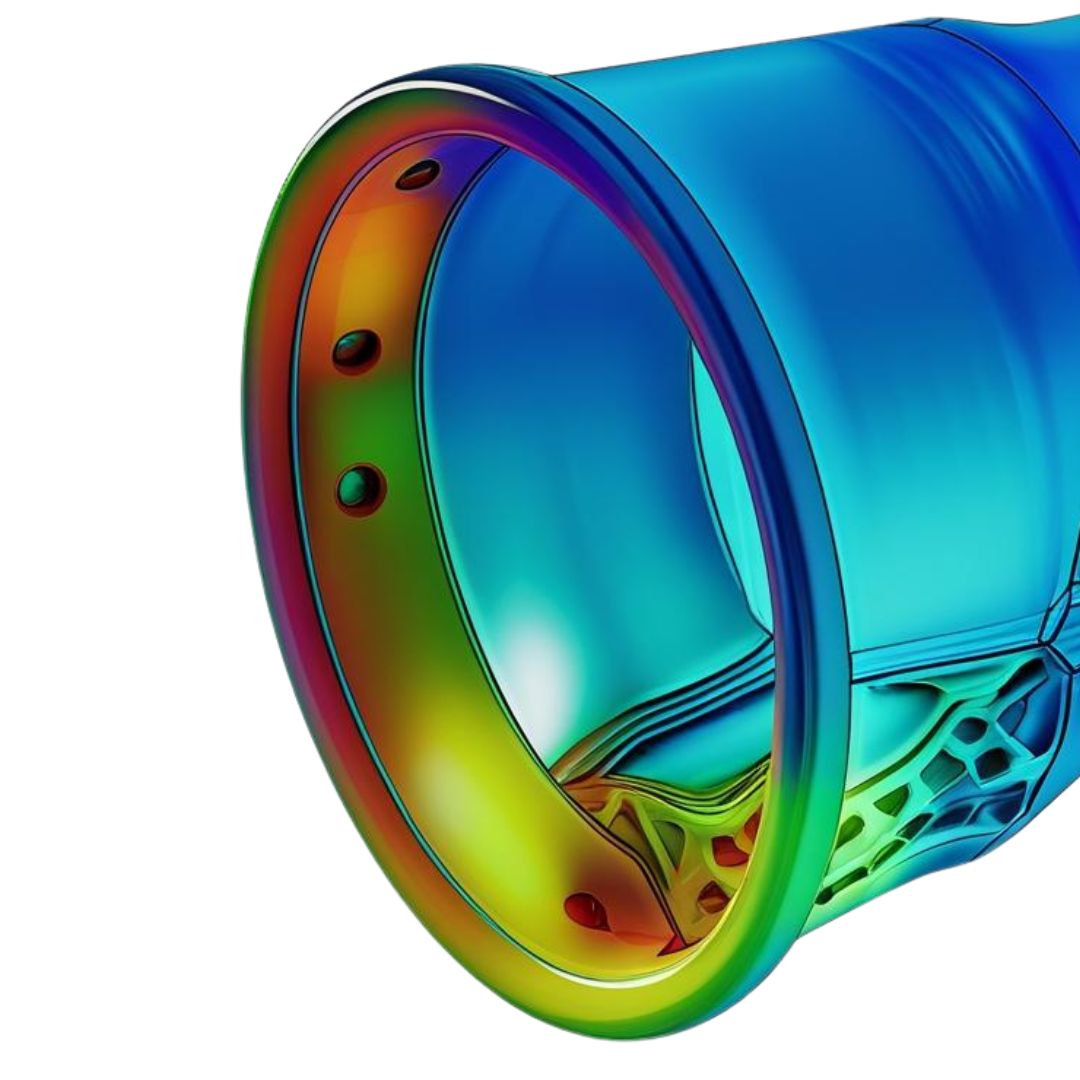

Structural Calculation and Thermal Simulations

Polymeric materials have chemical-physical characteristics that are very different from metals. To assess the feasibility and long-term reliability of plastic artifacts intended for structural use, dedicated tools, expertise, and an excellent understanding of compound behavior are required.

LATI provides a team of technicians and calculation tools to evaluate:

- the mechanical resistance of plastic artifacts subjected to all types of loads, even over extended periods

- the ability to manage thermal flows in heat exchangers, sensors, electronic housings, etc.

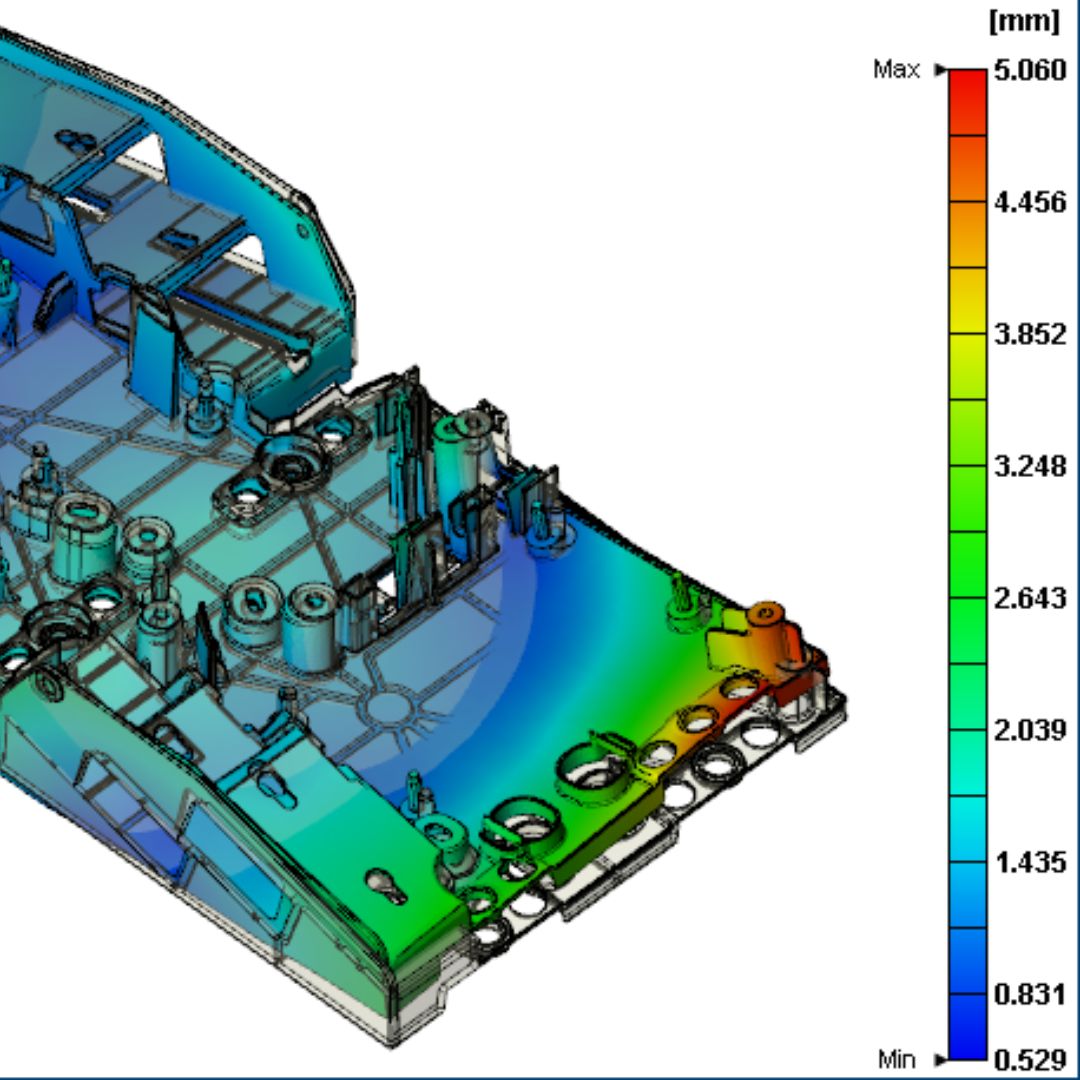

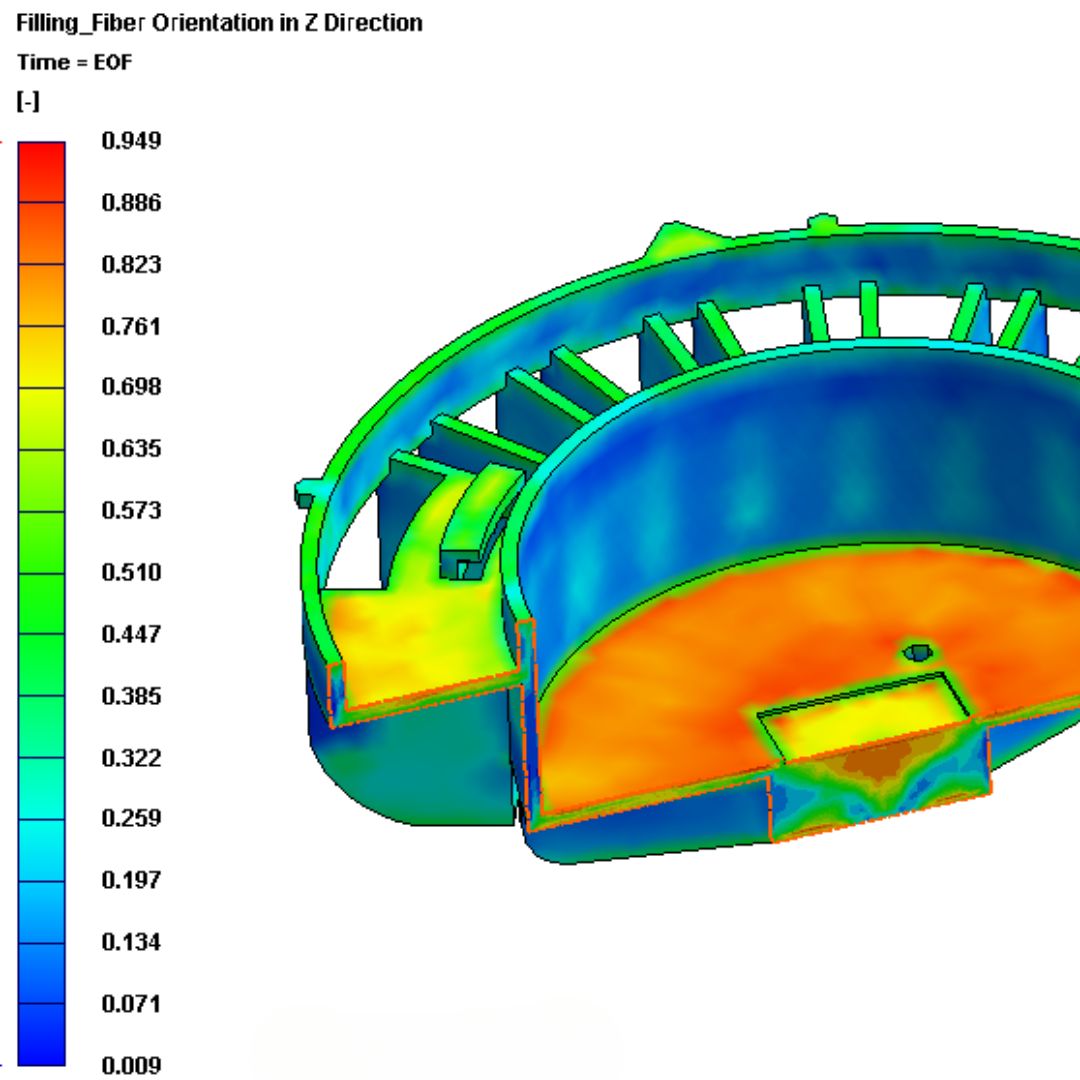

Fluid Dynamics Simulation

Our fluid dynamics simulation software allows for:

- Optimizing mold configuration and balancing of feed and cooling channels

- Calculating shrinkage and deformations to prevent dimensional stability issues and mold modifications

All this even on very complex compounds, thanks to numerous complete material characterizations conducted at the laboratories of the software producers themselves.

Co-design Support and Molding Process Optimization

- Verification of technical feasibility through structural, thermal, and fluid dynamic FEM simulations

- Optimization of component strength and durability

- Resolution of complex molding and deformation issues through finite element analysis and other techniques

Thermal Calculation for Heat Dissipation Improvement

By your Side to Develop your Project

Explore our Services and Discover how We Can Help You Achieve your Innovation and Sustainability Goals.

F.A.Q.

Frequently Asked Questions

LATI operates in close collaboration with material characterization laboratories and with the client who relies on us to optimize product design and solve existing artifact issues. Numerical simulations and molding sessions follow one another until the problem is completely resolved.

Yes, LATI offers advanced FEM simulations to estimate both the structural and thermal performance of your product and the outcome of the molding process. Simulations are especially helpful in optimizing the artifact’s geometry and solving problems before the product and mold are physically created.

The LATI laboratory is equipped for the complete mechanical characterization of LATI compounds, even at temperature and following specific conditioning. For fluid dynamic characterizations, LATI relies on the laboratories of the simulation software producers themselves. For any other characterization not available in LATI laboratories, the company relies on certified entities.

In the case of a project involving the use of LATI materials, the co-design service is offered free of charge, subject to internal evaluation of the project’s feasibility.

News & Events

PLASTPOL 2026 | LATI at the International Fair of Plastics and Rubber

FIP 2026 | LATI at the leading trade fair for plastics, composites, and rubber

INTERPLAS 2026 | LATI at the leading event for the plastics industry in the UK

KUTENO 2026 | LATI at the supplier fair for plastics processing

PLAST 2026 | LATI at the fair leading the evolution of the plastics industry