The Evolution of Technical Materials for the HVAC Sector

In the HVAC (Heating, Ventilation and Air Conditioning) sector, the demand for materials capable of ensuring thermal resistance, dimensional stability, and long-term durability is increasingly high.

PPS (polyphenylene sulfide) is currently one of the highest-performing technical polymers for manufacturing components subjected to extreme conditions, such as condensing boilers.

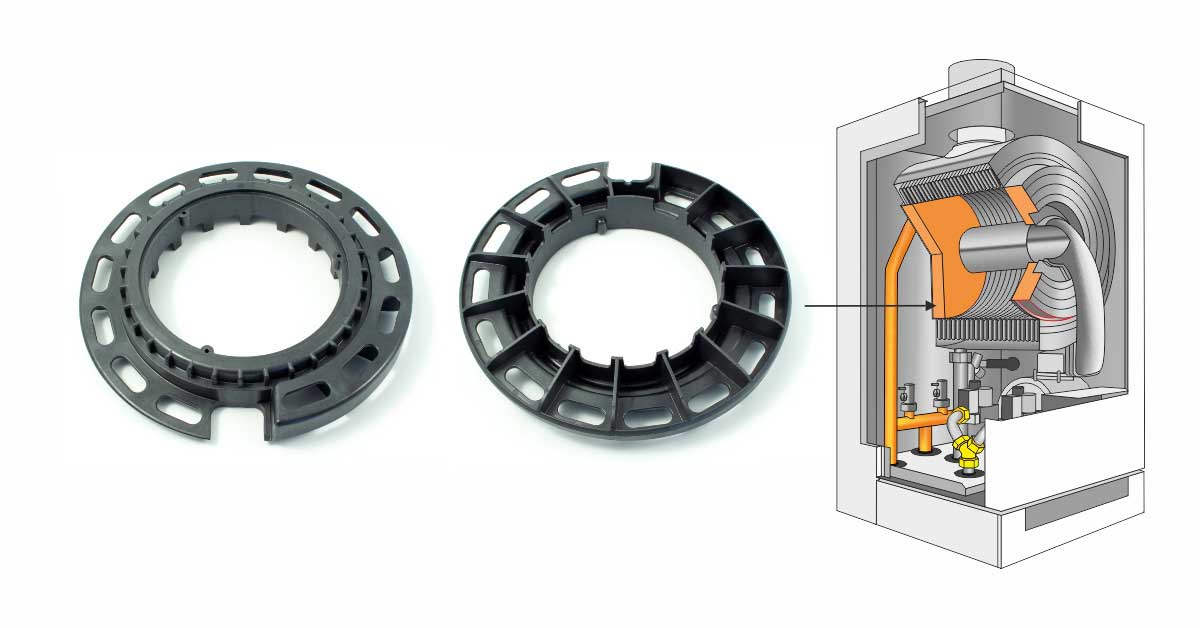

Among the main reference compounds, we find LARTON G/40, the PPS reinforced with 40% glass fiber developed by LATI Industria Termoplastici S.p.A., chosen by Wolf GmbH, a world-leading company in the production of heating and ventilation systems, for the production of compensation rings in the heat exchanger modules of their boilers.

PPS: a Technopolymer for Extreme Environments

The PPS (polyphenylene sulfide) compound stands out for its exceptional chemical inertness, high continuous thermal resistance above 200°C, and dimensional stability even in the presence of temperature and humidity variations.

These characteristics make PPS an alternative solution to metals and thermosets, ideal for metal replacement in technical components subject to thermomechanical stress.

The material is also suitable for the formulation of structural compounds reinforced with glass or carbon fibers, expanding the possibilities of use in areas that require geometric precision, reliability, and long operational life.

Application in Wolf Boilers: the LARTON G/40 Case

The Compensation Ring in the Heat Exchanger

In Wolf GmbH condensing boilers, the compensation ring represents a key component for managing the linear thermal expansion of the boiler metal.

For this application, Wolf engineers selected

- Maintaining dimensional stability even in continuous operating conditions above 200°C.

- Thermally insulating the rest of the boiler from the burner’s heat.

- Resisting chemical attacks, condensation, and combustion gases.

- Preventing thermomechanical fatigue, ensuring consistent performance over time.

Wolf’s experience has shown that the LARTON G/40 PPS compound represents the ideal compromise between rigidity, resistance, and reliability, ensuring the correct functioning of the heat exchanger in the long term.

Technical Support and FEM Simulation

The project was developed in collaboration with the LATI technical team, which provided FEM (Finite Element Method) simulation support to optimize filling, shrinkage, and deformations during the molding phase.

This analysis allowed for validating the component geometry, reducing waste, and ensuring compliance with the most stringent geometric tolerances.

Key Properties of PPS Compound for Condensing Boilers

| Property | Typical value | Benefit for the application |

| Continuous use temperature | > 200°C | High thermal resistance |

| Glass fiber reinforcement | 40% | Dimensional stability and rigidity |

| Chemical resistance | Excellent | Inertness to condensation and combustion gases |

| Density | ~1.65 g/cm³ | Weight reduction vs metals |

| Differential shrinkage | Very low | Constant dimensional precision |

PPS and Sustainability in Metal Replacement

In addition to technical advantages, PPS contributes to reducing environmental impact in HVAC applications.

The replacement of metal with thermoplastic compounds allows for reducing weight, processing energy, and resource consumption, while maintaining high mechanical and thermal performance.

Conclusion

Discover how LATI PPS compounds can improve the efficiency and durability of your components for boilers and HVAC systems.

Contact the technical team for advice on choosing the most suitable material for your applications.

FAQ – PPS Compound for Condensing Boilers

- Why use PPS in condensing boilers?

For its high thermal resistance, dimensional stability, and chemical inertness, ideal in high-temperature and acidic condensation contexts. - What is the advantage of LARTON G/40 compared to other PPS?

The high glass fiber content (40%) ensures rigidity and precision even under prolonged thermal stress conditions. - Can the PPS compound replace metal?

Yes, in many structural and technical applications where strength, lightness, and thermal insulation are required.