Preventing Electrostatic Charges in Handling Systems

In industrial handling systems, the formation of electrostatic charges poses a significant risk, both to operator safety and to the protection of electronic devices.

The accumulation of static electricity can generate high-voltage discharges following friction between insulating materials, potentially damaging sensitive components or igniting potentially explosive atmospheres.

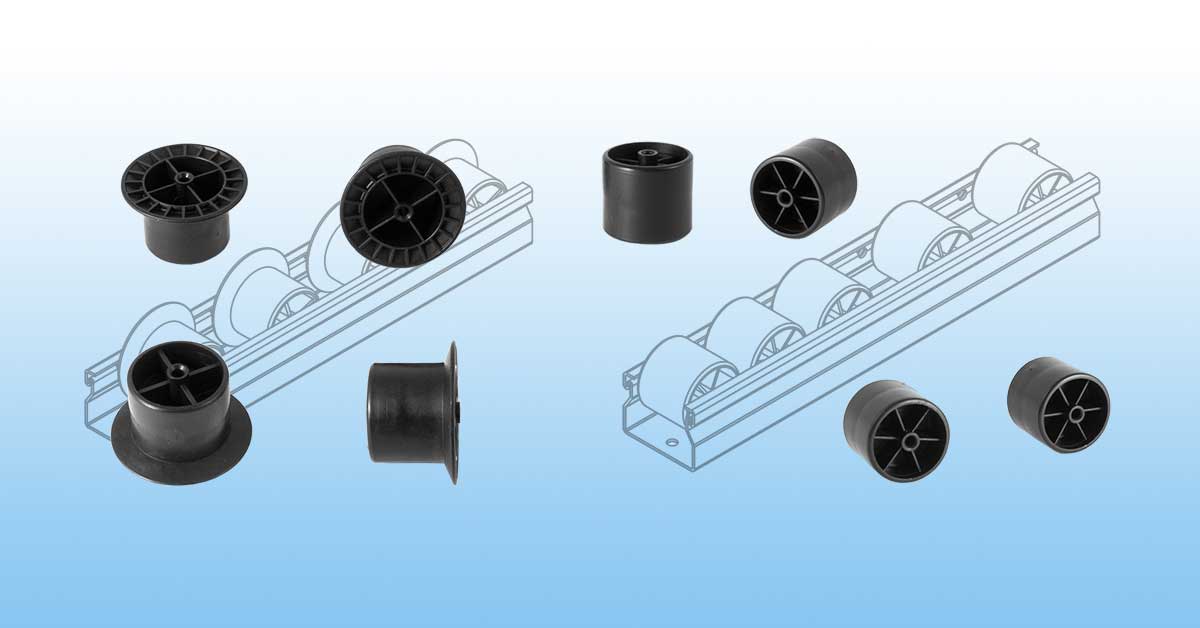

To eliminate these risks, the Spanish company Dinalager (Terrassa, Barcelona) has adopted a LATISTAT 47/7-03 antistatic compound from LATI Industria Termoplastici S.p.A. in the production of wheels for its light conveyor tracks for nastri trasportatori leggeri.

LATISTAT: High-Performance Antistatic Compound

Dinalager’s

- Excellent impact resistance.

- Ease of injection molding.

- No moisture absorption (non-hygroscopicity).

- Good dimensional stability up to 80°C.

The antistatic charge is achieved by adding a special conductive carbon black, with controlled morphology that ensures a highly effective percolating network even at low charge concentrations.

This allows maintaining good mechanical properties of the polymer and preserving impact and flexural resistance, essential for components subject to continuous impacts and rotations.

ATEX Directive Compliance and Guaranteed Safety

Dinalager’s goal was to ensure compliance with the European ATEX standard, which sets a maximum surface resistivity limit of 10⁹ Ω for materials used in explosion-risk areas.

The LATISTAT 47/7-03 compound far exceeds this requirement, with a surface resistivity of about 10² Ω, ensuring a wide margin of electrical safety.

The system is completed by a supporting metal guide, which allows perfect electrical continuity between wheels and structure, enabling controlled dissipation of charges to the ground.

Balanced Mechanical and Conductive Performance

The adoption of the LATISTAT antistatic compound has allowed combining electrical conductivity and structural robustness, maintaining high fatigue resistance in wheels subject to continuous rotation and directional changes.

| Properties | LATISTAT 47/7-03 | Standard PP | Result |

| Surface resistivity | ~10² Ω | >10¹⁴ Ω | ✅ Safe dissipation |

| Operating temperature | 80°C | 70°C | ✅ Greater stability |

| Impact resistance | High | Medium | ✅ High robustness |

| Permanent conductivity | Yes | No | ✅ ATEX compliant |

These features make LATISTAT ideal for applications where electrostatic safety meets mechanical durability, such as in the logistics, electronics, and industrial packaging sectors.

The LATISTAT Range: Solutions for Electrostatic Dissipation

LATI offers a

- Conductive carbon black

- Graphite and carbon fibers

- Carbon nanotubes (CNT)

These materials ensure electrical stability over time, even after processing, exposure to humidity, or temperature variations, offering customizable solutions for every type of industrial application.

Conclusion

Discover the LATISTAT range of antistatic compounds for conveyor belts and industrial systems.

Contact LATI experts to identify the most suitable formulation for your project and ensure constant safety and performance.

FAQ – Antistatic Compound for Conveyor Belts

- When is it necessary to use an antistatic compound in conveyors?

When the application involves friction between insulating materials or the risk of charge accumulation in ATEX environments. - What is the difference between antistatic and conductive material?

Antistatic material gradually dissipates charges, while conductive material instantly discharges them to the ground. - Does the LATISTAT compound maintain conductivity over time?

Yes, thanks to the stable dispersion of conductive carbon black in the polymer matrix.