In the field of industrial design, reducing the weight of components without compromising mechanical strength is an increasingly central challenge.

The lightweight thermoplastic compounds without blowing agent represent an innovative solution that allows for 20% lower densities compared to traditional materials, while maintaining high structural performance.

Lightness and Performance: a Challenge for Structural Polymers

In injection molded products, especially when using reinforced technical compounds, the specific weight tends to range between 1.4 and 1.6 g/cm³.

For many industrial applications, this already represents a significant advantage over metals, but in some sectors — such as automotive, robotics, electromechanics, and fast actuators — even a few grams of reduction can translate into tangible benefits:

- lower inertia of moving parts,

- faster response times,

- reduced energy consumption,

- optimization of movement dynamics.

Traditionally, density reduction in polymers has been achieved through blowing agents. However, these technologies present control limitations, non-uniform internal structure, and risks of mechanical weakening.

LATIMASS 67-04 D009: Lightweight Compound without Blowing Agent

A valid alternative to blowing agents is represented by lightweight thermoplastic compounds with hollow glass spheres, such as LATIMASS 67-04 D009.

This material allows for the production of light and strong products, thanks to the synergy between:

- a high-performance polymer matrix, based on reinforced polyamide, and

- hollow glass microspheres, with very low apparent density and undeformable spherical structure.

How Lightweighting with Hollow Glass Spheres Works

Unlike blowing agents, hollow glass spheres do not generate gas or irregular cavities within the material.

Thanks to their stable geometry, they maintain their shape during the injection molding process, creating a uniform and repeatable microstructure.

| Properties | LATIMASS 67-04 D009 | Standard reinforced PA compound |

| Density | 1.1–1.2 g/cm³ | 1.4–1.6 g/cm³ |

| Weight reduction | up to -20% | — |

| Mechanical strength | High | High |

| Dimensional stability | Excellent | Excellent |

| Lightweighting method | Hollow glass spheres | Chemical blowing agent |

| Side effects | None (no gas, no porosity) | Possible local weakening |

Advantages of the Lightweight Compound without Blowing Agent

The use of hollow glass spheres as a structural agent allows for simultaneous benefits in terms of weight, stiffness, and stability.

| Advantage | Technical description |

| Density reduction up to 20% | Without altering overall mechanical strength |

| Absence of internal porosity | No surface or filling defects in molding |

| Better material uniformity | Homogeneous distribution of spheres in the polymer matrix |

| Simplified processability | Compatible with standard injection molding equipment |

| Better thermal and dimensional stability | No deformation due to blowing gas |

| Eco-efficiency | Mass reduction = lower energy consumption and less CO₂ during use |

Applications of the Lightweight Thermoplastic Compound

The LATIMASS lightweight compounds find application in all sectors where weight, stiffness, and reliability must coexist.

Application Examples

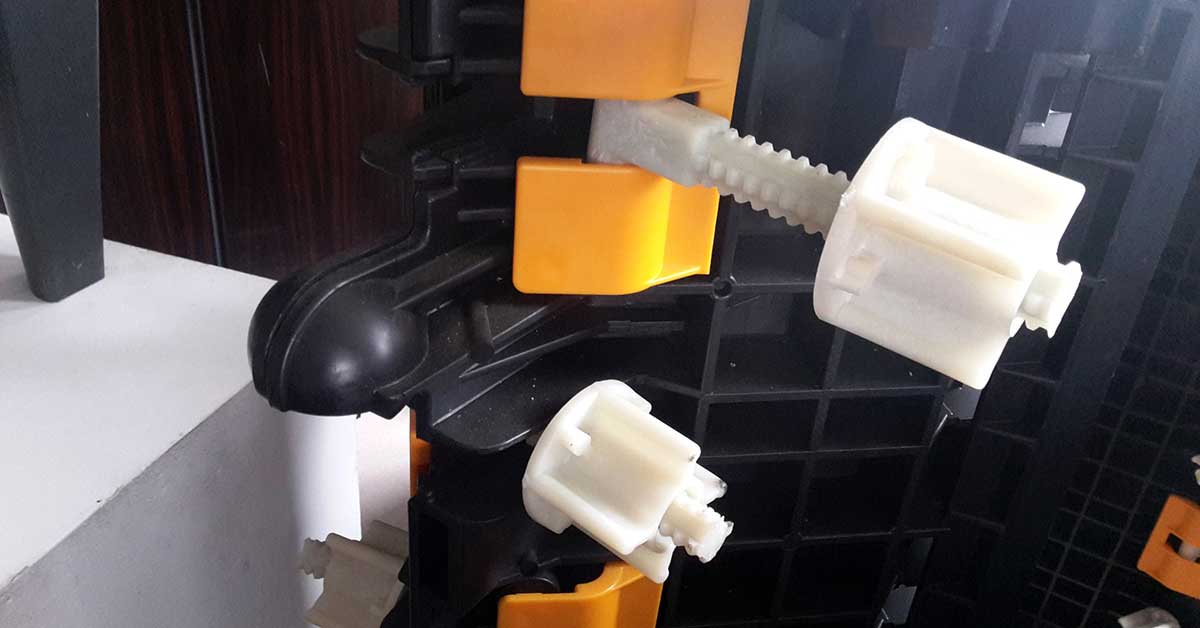

- Lightweight automotive components (engine covers, brackets, supports)

- Moving parts for actuators and servomechanisms

- Housings for electronic devices or industrial sensors

- Structural components for portable tools or collaborative robots

- Technical products where inertia reduction improves dynamic performance

Comparison: Lightweighting with Hollow Spheres vs Blowing Agents

| Feature | Hollow glass spheres | Blowing agents |

| Structural uniformity | Homogeneous and stable | Irregular, with gas cells |

| Mechanical strength | Unchanged | Often reduced |

| Dimensional precision | High | Variable |

| Production repeatability | High | Low |

| Process management | Simple, controllable | Complex, sensitive to temperature/pressure |

| Aesthetic appearance | Smooth and compact surface | Possible surface roughness or porosity |

Efficiency and Sustainability

In addition to technical advantages, lightweight compounds without blowing agent offer a tangible benefit also on the environmental level.

Reducing the mass of components means:

- lower consumption of raw materials,

- shorter cycle times in molding,

- lower CO₂ emissions during component use,

- and greater recyclability compared to expanded cellular polymers.

Performance and Mechanical Integrity

The LATIMASS 67-04 D009 can also be used as a lightening master batch to modify other structural compounds.

Thanks to its polyamide matrix, the material retains stiffness, tensile strength, and impact resistance comparable to standard grades reinforced with glass fiber.

Comparative tests show that the loss of elastic modulus is less than 5% compared to the reference material, with a density reduction of 20%.

FAQ – Frequently Asked Questions about Lightweight Thermoplastic Compounds without Blowing Agent

- How is lightweighting achieved without blowing agents?

Through the insertion of hollow glass microspheres into the polymer matrix, which reduce density without creating porosity. - Are the mechanical properties compromised?

No, the material structure remains compact and uniform. The mechanical performance remains comparable to traditional reinforced compounds. - Is it necessary to modify the molding process?

No, lightweight compounds can be molded with standard equipment, maintaining conventional process parameters.

Conclusions

Lightweight thermoplastic compounds without blowing agent, such as LATIMASS 67-04 D009, offer a new opportunity for designing lightweight and structurally solid components, ideal in contexts where weight affects performance, consumption, and dynamics.

💡 Do you want to reduce the weight of your components without compromising strength?

Request a LATI technical consultation to discover the most suitable lightweight compound for your applications and production processes.