PEEK, the Technopolymer that Replaces Steel and Titanium

In the chemical industry, materials used for the construction of pumps, valves and joints must guarantee mechanical resistance, thermal stability and chemical inertness.

For years, special steels and titanium alloys have been considered indispensable, but today high-performance thermoplastic compounds offer a lighter, more versatile and sustainable alternative.

Among these, PEEK (Polyetheretherketone) stands out as the reference structural technopolymer, capable of maintaining performance even under extreme conditions.

In its carbon fiber reinforced version, PEEK reaches levels of stiffness, conductivity and strength that allow its use as a replacement for traditional metals.

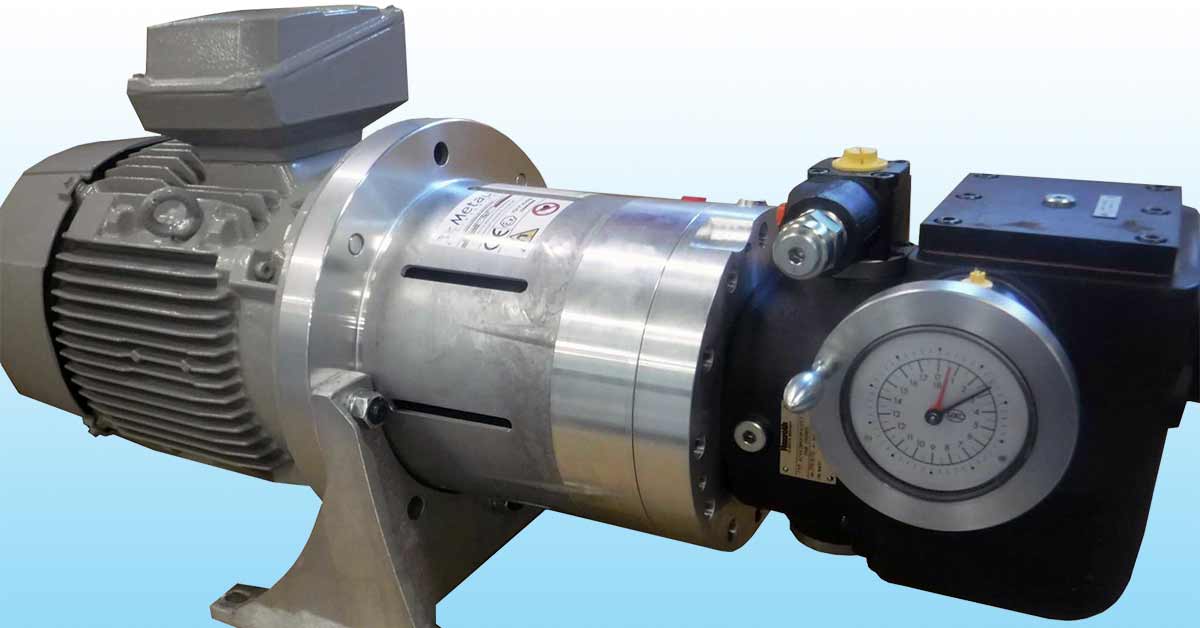

The Metau Engineering Case: PEEK Magnetic Couplings for the Chemical Industry

The Italian company Metau Engineering, specialized in hydraulic systems and solutions for the chemical sector, faced the challenge of improving the reliability of magnetic drive couplings used in the transfer of sensitive fluids such as polyurethane monomers.

These components require maximum sealing and separation between the moving part and the external environment, to avoid leaks, vibrations or seepage.

The key to the project is a separation bell subjected to very severe operating conditions:

Technical requirement | Typical value | Critical issue addressed |

Operating temperature | up to 100°C | Thermal deformations |

Internal pressure | up to 50 bar | Structural resistance |

Transmitted torque | up to 500 Nm | Stiffness and stability |

Operating environment | aggressive chemical substances | Chemical resistance |

LARPEEK 10 K/30: the High-Toughness Carbon Fiber Reinforced PEEK Compound

After a thorough testing phase, Metau Engineering chose LARPEEK 10 K/30, a PEEK-based compound reinforced with 30% by weight carbon fiber, developed by LATI Industria Termoplastici.

Main characteristics of LARPEEK 10 K/30:

- High-performance PEEK polymer base, stable up to 250°C continuously.

- High-toughness carbon fiber reinforcement for superior mechanical strength.

- High stiffness and elastic modulus, ideal for components subjected to dynamic loads.

- Intrinsic electrical conductivity, useful for ATEX certification.

- Excellent chemical resistance to acids, solvents and hydrocarbons.

- Dimensional stability even in the presence of constant pressures and stresses.

Thanks to these properties, the material has successfully passed deformation and resistance tests, ensuring safety and reliability even under prolonged thermal and mechanical load.

From Design to ATEX Certification

One of the key advantages of carbon fiber reinforced PEEK compound is its controlled electrical conductivity, which has enabled obtaining ATEX certification (Ex II 2GD c IIC TX) for the entire magnetic coupling system.

This requirement is fundamental for applications in potentially explosive environments, such as those typical of chemical and petrochemical industries.

The synergy between Metau Engineering and LATI has enabled optimization of the bell design through FEM analysis and durability testing, validating the material as a concrete alternative to steel and titanium.

The result is a lightweight, strong and durable component, with significant economic and production advantages.

Reinforced PEEK: Advantages over Metals

Properties | Stainless steel | Titanium | Carbon fiber reinforced PEEK |

Density (g/cm³) | 7,9 | 4,5 | 1,4 |

Thermal Resistance | Excellent | Excellent | Up to 250°C |

Chemical resistance | Good | Excellent | Excellent |

Workability | Limited (chip removal) | Difficult | Injection molding |

Electrical conductivity | High | High | Controllable (ATEX) |

Cost and recyclability | High | Very high | Excellent performance/price ratio |

The adoption of reinforced PEEK enables a weight reduction of up to 80%, eliminating corrosion problems and simplifying series production through molding.

PEEK Compounds: Solutions for Critical Applications

Carbon or glass fiber reinforced PEEK-based compounds find application in numerous high-performance fields:

- Chemical industry → pumps, valves, seals and magnetic couplings.

- Oil & Gas and ATEX → antistatic components resistant to high temperatures.

- Aerospace and Motorsport → lightweight and conductive structural parts.

- Medical and pharmaceutical → sterile parts resistant to sterilization cycles.

Thanks to their dimensional stability, chemical inertness and wear resistance, PEEK compounds today represent one of the most advanced alternatives to technical metals.

Learn more

Explore the LARPEEK range of carbon fiber reinforced PEEK compounds for high-performance applications and aggressive environments.

Visit www.lati.com to discover customized solutions for your sector.

FAQ – Carbon Fiber Reinforced PEEK Compound

- When is it convenient to use reinforced PEEK instead of steel?

When high chemical and thermal resistance is required, but also weight reduction and ease of processing. - Is reinforced PEEK compatible with ATEX environments?

Yes, thanks to the controlled conductivity of carbon fiber, components can be certified according to ATEX directive. - What is the maximum operating temperature of PEEK?

LATI PEEK compounds work continuously up to 250°C, maintaining mechanical integrity and dimensional stability.