Intra Lighting, a leader in design lighting, faces the challenge of LED light heat. In collaboration with LATI, it chooses LATICONTHER thermally conductive plastic materials for heat sinks. LATICONTHER 62 GR/50-V0 offers high thermal conductivity, resistance and fire safety. LATI’s thermally conductive plastic materials prove to be a winning choice for efficient thermal management and for developing lightweight and sustainable products.

Conducting LED Light Heat: Intra Lighting’s Challenge

Intra Lighting is a Slovenian company and European leader in the production of design luminaires and intelligent lighting solutions. Characterized by great attention to detail, Intra L. lamps combine forms, designed by the world’s best designers, with functionality that must always be perfect and in line with regulatory and project requirements.

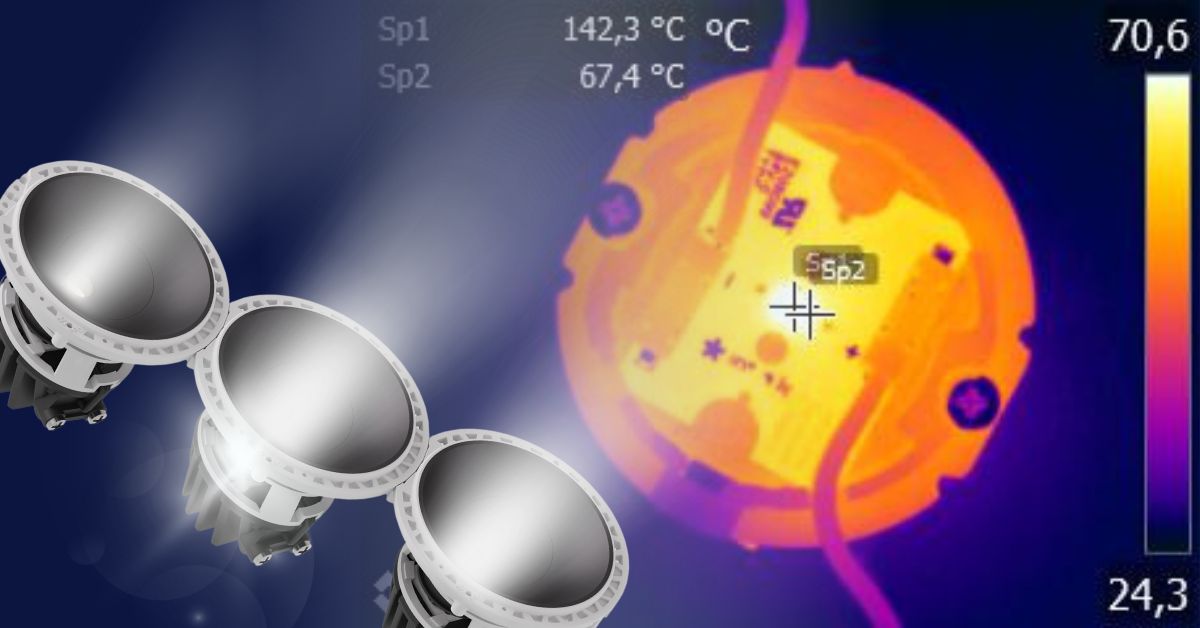

Even in the world of Intra products, LED light sources have made their entrance, replacing traditional sources and bringing with them completely new technical and technological requirements. Among these is also the need for accurate cooling of the electronics used to generate even very intense light beams.

As is well known, to safely manage the heat flow that accompanies power supplies and LEDs, aluminum radiating elements are normally used: from simple extruded profile sections to complex die-cast geometries, intended for further finishing operations.

LATI Thermally Conductive Plastic Materials for Metal Replacement

For the production of heat sinks intended for a new series of recessed spotlights, Intra wanted to direct designers’ attention toward metal replacement using LATI’s LATICONTHER thermally conductive compounds.

Perfect management of the heat generated by LED electronics requires that the dissipating element not only be as effective and efficient as the metallic one, but also show extremely high dimensional stability, essential to ensure the flatness of the seat and the best contact between the surfaces involved in thermal exchange. Then thermal resistance is needed, which is obvious with metal but must be verified with polymers.

Finally, safety requirements for this specific project require that plastic parts also be flame resistant to prevent any possible fire in case of unexpected events.

LATICONTHER 62 GR/50-V0: Thermal Conductivity, Resistance and Flame Retardancy

The material successfully selected by Intra Lighting is LATICONTHER 62 GR/50-V0, the flame-retardant version of the established analogous compound based on PA6 and loaded with 50% graphite.

Capable of thermal conductivity well above 10 W/mK, this specific grade of the LATICONTHER family continues to demonstrate the feasibility of reliable solutions from thermal, structural and mechanical standpoints, thanks to the formulation appropriately optimized to increase resistance to external stresses.

Flame retardancy is guaranteed by UL certification which for the product in question shows a UL94 V0 rating – the highest – down to a minimum thickness of 0.75 mm.

Strong in their physical properties, great versatility and competitive costs, LATICONTHER materials continue to prove over time to be a winning solution both in thermal management and in developing lighter and more sustainable products compared to conventional solutions.

Want to understand how LATI can help you and your company develop winning projects?

Contact us here!