In the food industry, product safety is an absolute priority. One of the most frequent causes of batch and supply recalls is accidental contamination with plastic fragments from components, tools, or processing lines.

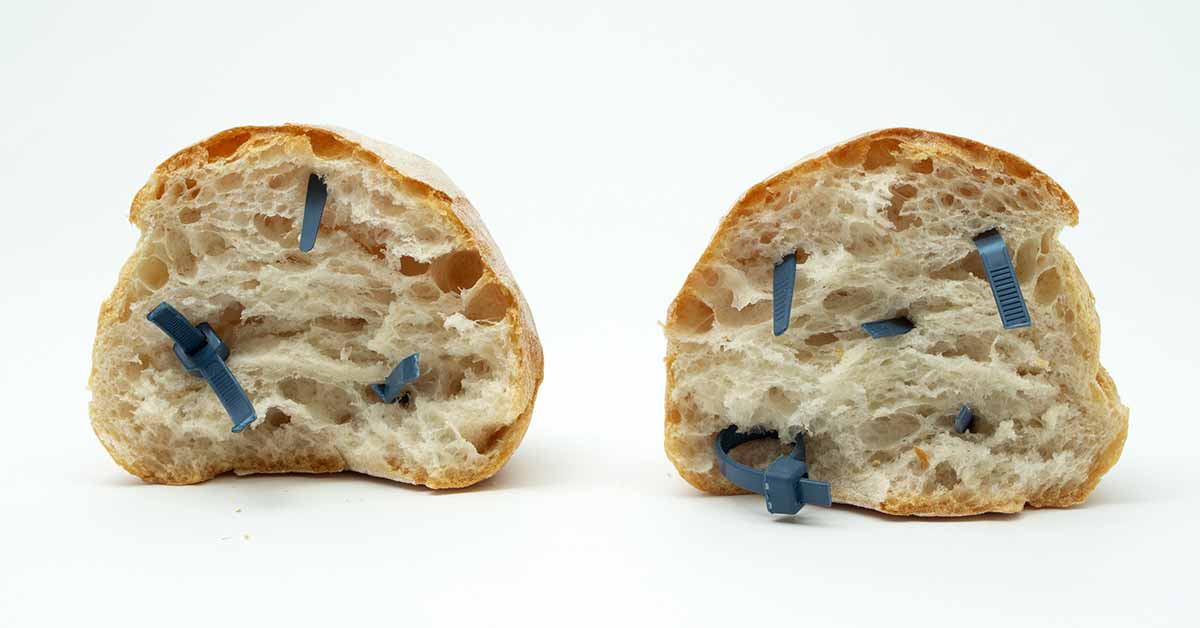

To avoid these risks, detectable thermoplastic compounds have been developed, designed to be identified by metal detectors and X-ray systems, even when dealing with microscopic particles.

The Problem of Plastic Contamination in the Food Supply Chain

Every year, numerous food companies have to deal with product recalls from the market due to the presence of plastic foreign bodies.

These events not only lead to serious economic losses, but can compromise years of reputation and trust built with consumers.

Traditional plastics, in fact, are not detectable by standard quality control systems based on magnetic metal detectors. Even the smallest chip can go unnoticed and reach the end consumer.

Solution: the use of detectable compounds, designed to generate a magnetic or radiopaque response, allows for the interception of even the smallest contaminating particle during packaging or inspection of the finished product.

LATI MDT Detectable Compound Technology

LATI has developed the MDT (Magnetically Detectable Thermoplastics) range, a family of detectable thermoplastic compounds designed to ensure maximum food safety.

These materials are loaded with ceramic powders and magnetically active additives, capable of locally altering the magnetic field and making every plastic part detectable by metal detectors or X-ray systems.

| Technical property | Description |

| Detectability | Compatible with metal detectors and X-rays |

| Composition | Thermoplastic polymers filled with ceramic powders |

| Polymer base | PP, PA, PEEK, PPS, depending on application requirements |

| Food suitability | Compliant with European and international regulations |

| Processability | Injection molding, extrusion, or calendering |

| Mechanical strength | High even under dynamic conditions |

Applications of Detectable Compounds in the Food Industry

MDT compounds are used in a wide range of applications related to food production, processing, and packaging.

Examples of Producible Components

- Crates, containers, and lids for food processing lines;

- Conveyor belts and guides for handling systems;

- Maintenance tools and accessories (paddles, wrenches, pliers, spatulas);

- Fastening and closing elements in packaging machinery;

- Fittings and housings for sensors or valves in contact with food.

Thanks to their thermal and chemical stability, MDT compounds can also be used in process environments at high temperatures or with aggressive cleaning agents.

Performance in Extreme Operating Conditions

LATI offers MDT compounds formulated on different polymer bases to respond to specific operating conditions:

| Base type | Distinctive properties | Typical applications |

| PEEK / PPS | Resistance up to 250°C | Components for sterilization or cooking lines |

| PA / PPA | Rigidity and mechanical toughness | Structural parts of packaging plants |

| PP | Excellent chemical resistance | Components exposed to frequent cleaning and sanitization |

| TPE / Elastomers | Flexibility and shock absorption | Gaskets, cushioning elements, safety tools |

All MDT compounds guarantee impact resistance, low hygroscopicity and absence of harmful substance release, complying with FDA and EU 10/2011 requirements for food contact.

Certified Safety and Food Compliance

LATI’s detectable compounds for the food industry are certified for direct or indirect food contact.

Toxicological safety and migration tests guarantee non-transfer of contaminants even under high temperature and humidity conditions.

| Certification | Reference standard | Description |

| Food suitability | Reg. (EU) 10/2011 | Plastic materials and articles intended to come into contact with food |

| FDA 21 CFR | United States | Compliance standards for polymeric materials |

| ISO 22000 / HACCP | Food safety systems | Applications compatible with self-control procedures |

Benefits of Using MDT Detectable Compounds

| Advantage | Description |

| Contamination prevention | Immediate identification of plastic fragments in the finished product |

| Reduction of recalls | Avoids economic losses and reputational damage |

| Regulatory compliance | Materials suitable for food contact |

| Application adaptability | Available on PP, PA, PPS, PEEK, TPE bases |

| Mechanical reliability | Resistance to impacts, vibrations, and detergents |

| Total detectability | Compatible with metal detectors and X-rays |

Integration into Production Processes

The replacement of standard components with MDT detectable compounds does not involve significant changes to industrial processes.

The materials are easily processable with existing molds and machinery, with a marginal economic impact and a huge advantage in terms of safety and compliance.

🔧 A small investment in replacing traditional plastic components with MDT materials can prevent potentially disastrous incidents, protecting brand, product, and consumer.

FAQ – Frequently Asked Questions about Detectable Compounds for the Food Industry

- How do metal detector-detectable compounds work?

They contain magnetically active additives that alter the magnetic field, allowing the detection of plastic fragments even of minimal dimensions. - Are MDT compounds compatible with European food regulations?

Yes, all LATI MDT materials comply with Reg. EU 10/2011 and FDA 21 CFR regulations, ensuring safety for food contact. - In which applications is the use of detectable compounds recommended?

They are ideal for components of production lines, tools, conveyor belts, and accessories intended for food or pharmaceutical plants.

Conclusion

The detectable compound for the food industry is an essential solution for ensuring total traceability and safety in food production.

Thanks to LATI MDT formulations, companies can reduce contamination risks, optimize quality controls, and fully comply with international standards.

Want to improve the safety of your food plants?

Request a LATI technical consultation to identify the most suitable detectable compound for your process conditions and type of food processed.