The Living Farming Tree is the first vertical garden inspired by biophilic design, designed and developed by Hexagro.

Advanced ideas require materials and solutions that meet the challenge: this is why Hexagro chose LATI and its LATICONTHER thermally conductive compounds to create lightweight, high-performance, and sustainable heat sinks.

Thanks to this collaboration, it was possible to reduce weight, complexity, and carbon footprint compared to traditional metal solutions, while maintaining maximum thermal efficiency for the LED lights necessary for plant growth.

A Green Dream: Vertical Farming According to Hexagro

The mission of Hexagro is clear: to ensure access to healthy food for everyone, everywhere, thanks to vertical farming technologies.

The company envisions a future where it is possible to grow food even in cities, reconnecting people with nature through innovation.

The Hexagro team is a mix of engineers, designers, and agronomists from more than six countries, united by a common vision.

Alongside technological innovation, Hexagro also pursues a strong social commitment: with the Hexagro Siembra Vertical Social project in Colombia, for every Poty garden sold, new modules are installed to support local communities.

Thanks to this sustainable vision, Hexagro has received recognition from organizations such as the Ellen MacArthur Foundation and the Solar Impulse Foundation.

Living Farming Tree: the Vertical Garden of the Future

The Living Farming Tree allows nutritious plants to be grown indoors with a modular design suitable for any space, even in offices.

It uses aeroponic technology, which mists water and nutrients directly onto the roots, ensuring resource savings, automation, and optimized growth.

Thanks to smart LED lights and automatic irrigation, anyone can enjoy healthy, safe, and sustainable cultivation — even without a “green thumb.”

LATICONTHER Compounds for Thermal Management of the Living Farming Tree

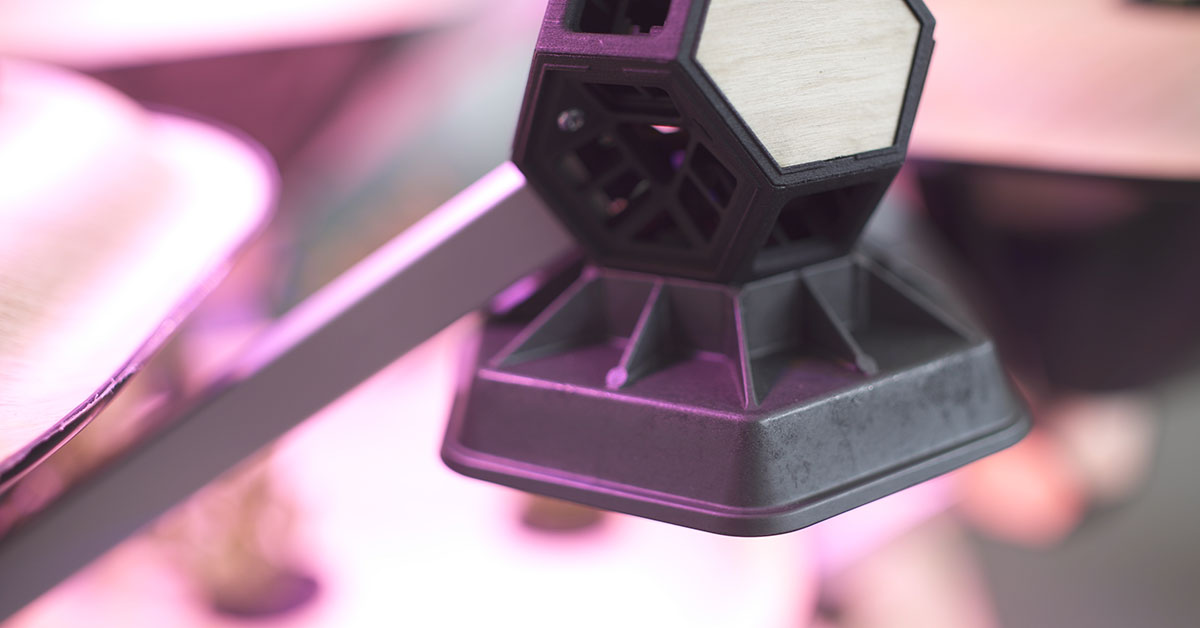

One of the key elements of the Living Farming Tree is the heat sink that houses electronics, lenses, and LED PCBs.

For this component, Hexagro was looking for a material that is lightweight, efficient, and has a lower environmental footprint compared to aluminum.

With the support of the UK molder Protool Plastics, LATICONTHER 62 GR/50 was chosen, a thermally conductive compound formulated by LATI based on PA6 loaded with 50% graphite.

The Advantages of LATI Material:

-

Weight halved compared to aluminum

-

High thermal conductivity (>10 W/mK) for optimal heat management

-

Design freedom and increased production efficiency

-

Reduction in energy costs and no post-processing required

-

Mold longevity and perfect production scalability

These features allowed Hexagro to improve thermal performance while simultaneously reducing weight, costs, and environmental impact of the product.

LATI Technical Assistance: from Simulation to Success

The LATI technical team supported Hexagro at every stage of the project:

-

Selection of the most suitable material

-

Geometric optimization of the heat sink

-

FEM simulations and molding analysis

Numerical checks confirmed the effectiveness of the cooling and mechanical coupling between the heat sink and LED PCB.

After the prototyping phase, injection production fully validated the solution.

A Greener and more Sustainable Future

“Replacing metal with plastic compounds is a challenge that requires vision and courage.

Our greatest satisfaction is seeing intelligent, high-performance, and sustainable solutions come to life.”

— Luca Posca, Technical Assistance & Marketing Director LATI

“Thanks to the collaboration between Hexagro, LATI, and Protool, we have improved performance, costs, and scalability, while maintaining the product’s aesthetics.”

— Team Hexagro

Expertise, technology, and vision: three words that describe a collaboration capable of bringing innovation, well-being, and nature into urban spaces.

Who wouldn’t want a Living Farming Tree in their daily life?

🎥 Watch the video dedicated to the case study!