New Frontiers for Additive Manufacturing

Even in the world of 3D printing, new benchmarks and increasingly specialized market niches are emerging.

In this scenario, Profplast, a Polish company active in the filaments for additive manufacturing sector, has chosen to focus on high-tech products aimed at customers requiring specific performance, such as thermal or electrical conductivity.

Profplast’s Experience and the Choice of LATI Compound

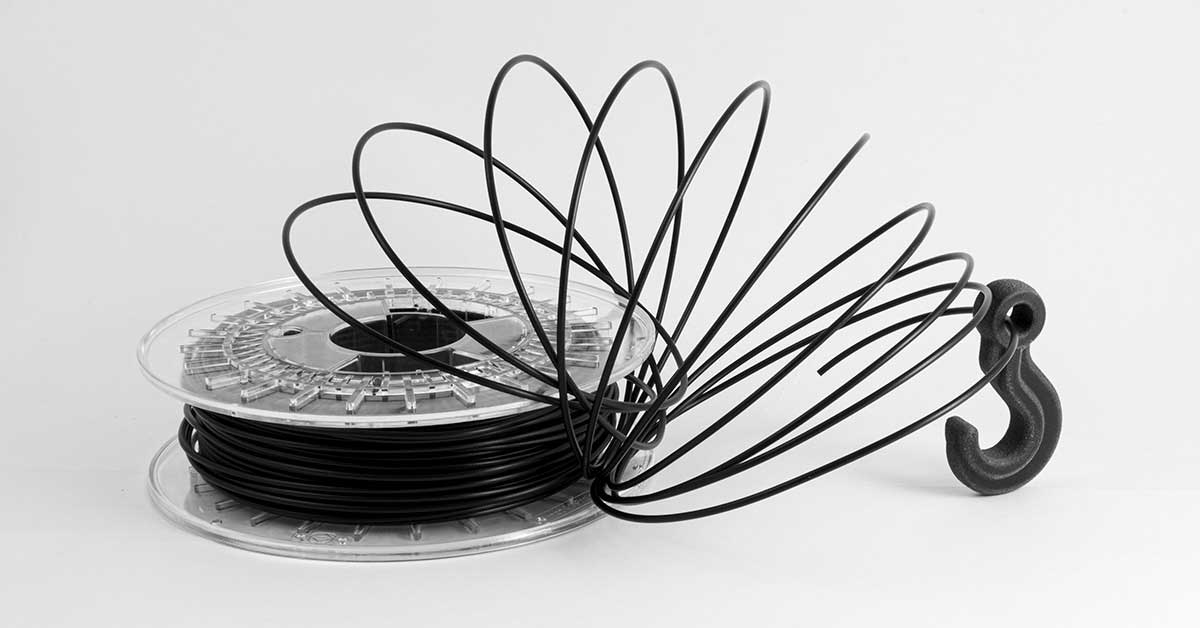

Thanks to Profplast’s extensive experience in complex material extrusion and the creation of technical profiles, the company has managed to develop a continuous filament from LATAMID 12 H2 K/15, a PA12-based compound reinforced with 15% carbon fiber, formulated by LATI Industria Termoplastici.

This choice has resulted in a highly performant material, characterized by dimensional stability, mechanical strength, and excellent workability, even during extrusion and winding phases.

Performance and Printing Parameters

Depositing a carbon fiber reinforced filament traditionally presents several challenges—from diameter control to thermal shrinkage management—but LATAMID 12 H2 K/15 has exceeded all expectations.

The material performs excellently both during the extrusion phase and in printing, with optimal parameters of:

-

Deposition speed: 150 mm/min

-

Printing temperature: approximately 240°C

-

Reinforced nozzles: to withstand abrasion induced by carbon fibers

The result is a stable and precise filament, ensuring components with excellent mechanical and dimensional properties.

Nanocarbon: the Technical Filament for Industrial Applications

The filament is currently marketed by Finnotech (f3dfilament.com) under the name Nanocarbon, and is designed for applications where common materials like ABS, PET-G, or PLA do not offer sufficient performance.

The main features of Nanocarbon include:

-

High stiffness and robustness

-

Excellent dimensional stability

-

Resistance to moisture and chemicals

Thanks to these properties, the material is suitable for aerospace, medical, optical, robotic applications and in the industrial automation sector.

LATI and Innovation in 3d Printing

LATI’s contribution to the development of the additive manufacturing sector continues with new formulations for the spinning of special compounds, including:

-

Radiopaque and metal detector detectable materials

-

Thermally and electrically conductive compounds

-

High-performance reinforced and filled grades

LATI thus confirms its role as a technological partner for companies seeking advanced and sustainable solutions in professional 3D printing.