Miniaturization and its Technical Challenges

Miniaturization is a key technological process in many sectors of the electrical and electronic industry.

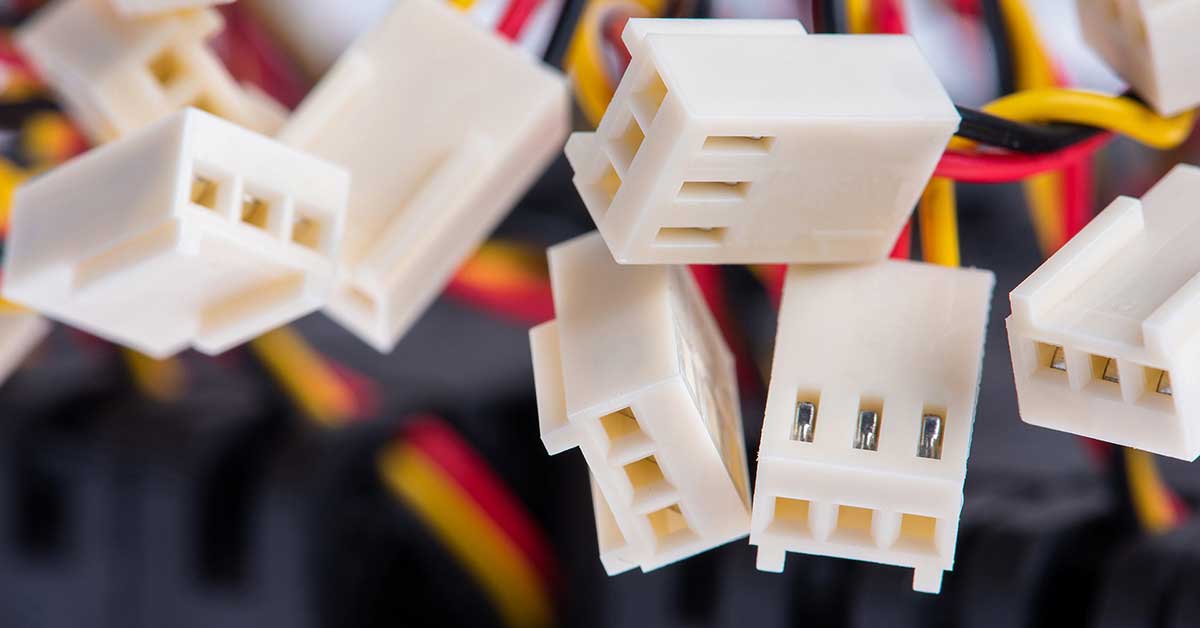

Reducing the size of circuits, active and passive components, connectors and housings enables more compact, lightweight and high-performance devices — without compromising functionality.

Today miniaturization no longer concerns only computing or portable devices: it involves actuators, relays, switches, regulators, SMD components and systems for appliances, e-mobility and circuit-breakers.

However, the increasing density of electronic components per unit area introduces new critical issues, such as:

accumulation and management of heat;

need to guarantee high performance and stability;

compliance with increasingly strict fire safety regulations.

Materials for Miniaturization: Safety at Thin Thicknesses

To meet the requirements of the E&E (Electrical & Electronics) sector, the materials used must offer flame-retardant behavior and dimensional stability even at very reduced thicknesses.

LATI has achieved this objective with two new-generation technical compounds that have obtained UL94 V0 certification at only 0.4 mm thickness:

LATAMID 66 H2 G/25-V0CT1

PA66 reinforced with 25% glass fiber, suitable for structural components and housings.LATAMID 66 H2PX-V0

PA66 toughened with elastomers, ideal for connectors and components requiring flexibility and resilience.

Both materials use brominated flame-retardant additives and guarantee flame and glow wire resistance, as required by IEC 60335 standard for household appliances.

Mechanical Performance and Thermal Stability

LATAMID 66 H2 G/25-V0CT1, thanks to glass fiber reinforcement, offers excellent rigidity and thermal stability even at thin thicknesses. It is ideal for voltage component supports, housings and structural parts, and ensures easy and precise molding.

LATAMID 66 H2PX-V0, instead, stands out for its resilience and flexibility, making it perfect for the production of connectors and components subject to dynamic stress.

Reliable Solutions for the Electronics of the Future

The range of LATI flame-retardant compounds offers safety and reliability for increasingly compact and high-performance applications, in line with the demands of modern microelectronics.

These materials represent a concrete response to the challenge of miniaturization, combining mechanical performance, heat resistance and electrical safety in a single solution.

For further information and detailed technical data sheets, visit 👉 www.lati.com