Table of Contents:

Back to table of contents

Hexagro's mission is to guarantee everyone access to healthy food. How? Through vertical farming technologies. This start-up’s dream is to allow food production in urban settings, in places that once would never have been considered suitable. Basically, it is all about putting people back in touch with nature, through technology.

Diversity, multiculturalism and a mix of skills are the ingredients that make the Hexagro team unique: its engineers, designers, project managers, marketing experts, agronomists come from more than six countries.

The company is very aware of the social implications of what it does. Poty, the bigger version of Living Farming Tree, is a modular vertical garden system with automatic irrigation. For each Poty its sells, the company installs new modules through Hexagro Siembra Vertical Social, an affiliated company that works to support disadvantaged communities in Colombia.

Thanks to its commitment and activity, Hexagro received important awards from the Ellen MacArthur Foundation and the Solar Impulsa Foundation.

Back to table of contents

Thanks to the use of sophisticated technologies, the Living Farming Tree makes it possible to grow, indoors, highly nutritious varieties of plants. It is a modular solution, suitable in any setting, that allows nature and well-being to be introduced anywhere, even the office. No soil is required: using aeroponic technology, water and nutrients are sprayed directly on the roots of the plants ensuring optimal use of resources. The level of automation is such that this vertical garden is ideal even if you haven’t got green fingers. What is more, the combination of automatic irrigation and correct intensity of the LED lights ensures optimised, safe and rapid plant growth.

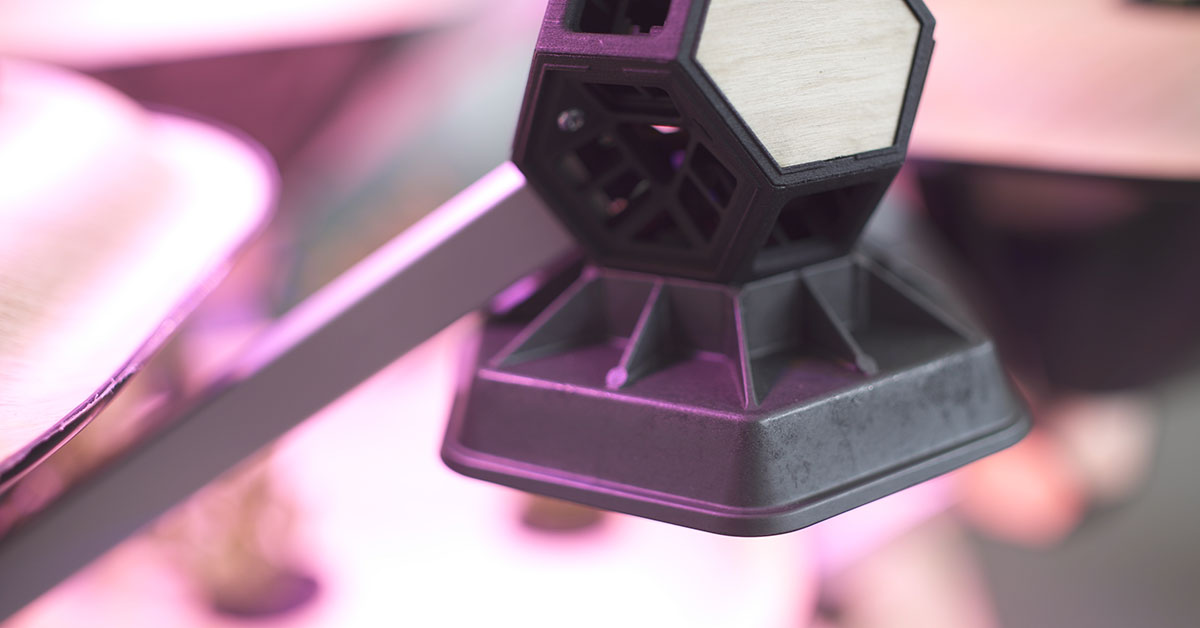

The heat sink for the lamp is one of the main components of the Living Farming Tree. This part is structurally connected to the joint, which is also made of polymer, and it houses the PCB for the LED lights, lenses and electronics. Hexagro was looking for a lighter weight, more manageable material with a better carbon footprint than traditional aluminium solutions. So, it turned to Protool, a British injection moulder, active on the UK, EU and global markets, that also specialises in the production of heat sinks made of engineering polymer. Protool advised Hexagro to use LATICONTHER 62 GR/50, the thermally conductive material formulated and produced by LATI that it itself already uses in several of its current products.

By using this material, consisting of a PA6 matrix reinforced with 50% graphite, the start-up has managed to reduce the weight of the component and increase its dissipative capacity, while also gaining greater freedom with regard to the shapes and design. The main pluses of the plastic solution are, in fact, the density of the material, which is half of that of aluminium, itself already very light, and the exceptional thermal conductivity, which allows the radiant element to safely disperse the heat produced by the LEDs, ensuring a low working temperature. Furthermore, it has significantly reduced the costs of the project since not only is the polymer lighter and less expensive than metal, its processing uses a fraction of the energy used to process aluminium and it does not require any post-processing after injection moulding.

Scalability is also a key issue for Hexagro, and LATI’s product meets this need. Indeed, it is not aggressive for the equipment and ensures that moulds have a long life even when they are used for large production runs.

Back to table of contents

LATI’s technical assistance team enthusiastically took up the challenge laid down by Hexagro: to verify the feasibility of the transition from aluminium to polymer and thus simplify the original structure of the heat sink. Initially, in fact, the project entailed the assembly of several materials and a more complex structure. The LATI team therefore helped the start-up to select the most efficient material, and optimise the geometry of the part, recommending the necessary improvements, such as the addition of fins and reinforcements where needed. Verification, in numerical terms, of the cooling effectively provided by the plastic radiator was followed by the moulding simulation step: the injection gate position, cooling system and mould layout were all evaluated to ensure there were no deformation that might compromise the coupling between the heat sink and the PCB and therefore the effectiveness of the cooling. The validity of the solution was first tested on prototypes and then confirmed on injection-moulded pieces.

“Replacing traditional metal solutions with plastic compounds is a complex challenge that only bold, visionary designers can take on. Our task is to offer specific and cutting-edge technological expertise to resolve difficulties and doubts. The most satisfying thing for us is seeing the results of many different collaborations materialising in the form of smart, high-performing and competitive products” says Luca Posca, Technical Assistance and Marketing Director at LATI.

"Thanks to the cross collaboration between Hexagro, LATI and Protool Plastics, we have addressed different challenges with a unique solution. Using the new LATICONTHER thermo-conductive material we have managed to produce our heat sink by injection moulding, reducing the number of parts, the weight and the costs and optimising the dissipation of the heat produced by our Living Farming Tree’s LED horticultural lights. We have achieved better performances in terms of energy consumption and production scalability, while respecting the aesthetics of the product."

Expertise, technology and vision are the basis of this collaboration, which looks to the future with hope and optimism. Who could possibly not want a Living Farming Tree to hand?