LATI recently decided to invest its own know-how in engineering thermoplastic compounds in the world of 3D printing, an exponentially growing sector with a future that is still in full evolution.

The collaboration with Ciceri de Mondel (Filoalfa) was born out of this inspiration and aims to design innovative materials for the production of filaments for frontier applications.

Products developed from this fusion of knowledge should be accessible to both the industrial and consumer market in order to ensure the feasibility of molded parts with not only a good aesthetic appearance, but also advanced technical features.

Filaments proposed should, of course, meet process requirements connected with conversion technology, that is, flexibility, dimensional stability, and 3D printability. So to ensure maximum usability of the offered product, a modified PLA was chosen, which is a biopolymer obtained from sustainable sources, processable by any 3D printer due to its physical properties.

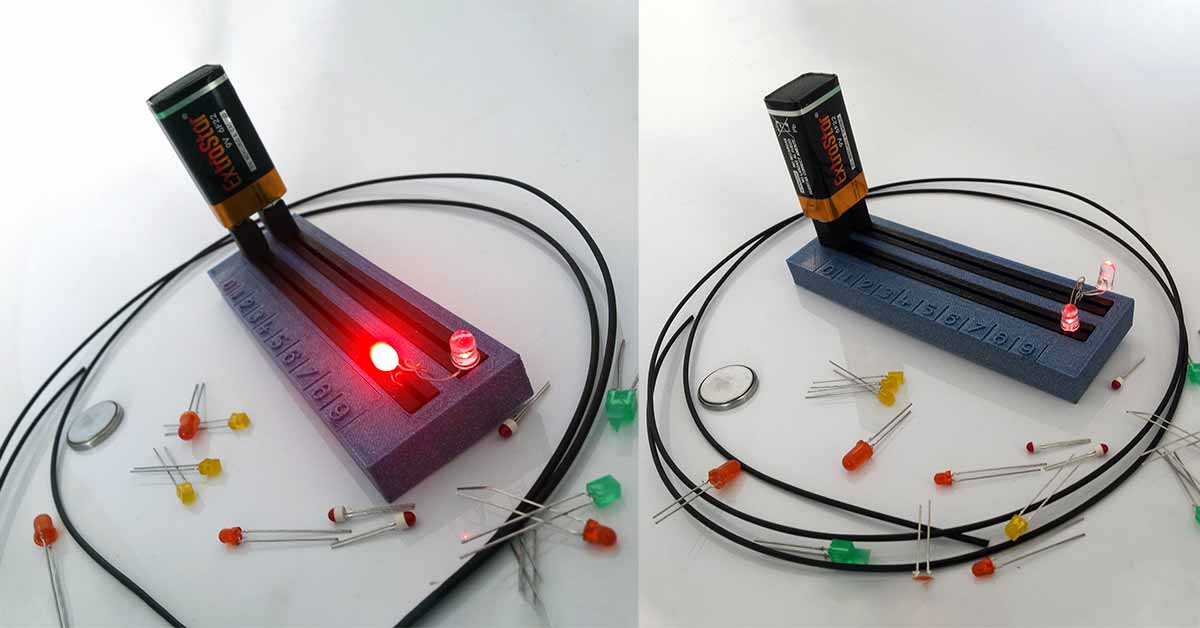

LATI’s first proposal is an electrically conductive thermoplastic compound obtained by formulations containing frontier materials, among which carbon nanotubes. As observed experimentally, LATI electrically conductive filament allows the transfer of small currents, and thus of signal and information.

The deposition of conductive tracks by simple 3D printing potentially allows innovative applications, e.g. in the medical, electrical/electronic, and telecommunications sector.

The electrical behavior of the LATI filament is non-ohmic and has a typical volume resistance of about 10 ohm*cm.

This property is typical of many semiconductors and is still being studied, but it is already clear that the maker will be able to find answers for the development of new applications with high technology content.

This is the purpose of LATI and Filoalfa: to act in concert to offer 3D printers finally accessible to everyone, as well as filaments developed from high technology synthetic materials.

The push for innovation in the industry, along with the enthusiasm of individual makers, will lead to flexible and customizable applications accessible to everyone and technologically unthinkable until yesterday.