As is known, the costs associated with the withdrawal from the market of entire supplies of finished product due to quality or safety problems may be really significant.

For a company operating in the food sector, this is a huge risk in terms of image, reliability, and credibility, which are elements often built with years of strenuous industrial and marketing choices.

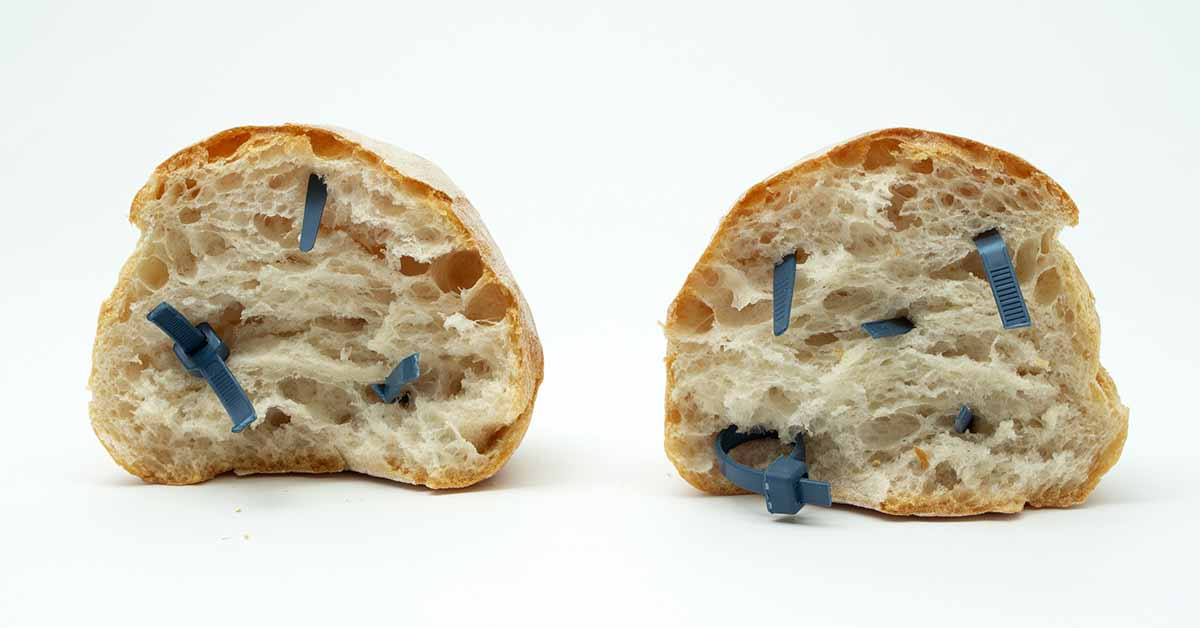

One of the most frequent causes of withdrawal is the food contamination with plastic parts from the various stages of production, conversion, packaging and storage.

The release of harmful substances may also occur in the presence of foreign elements in the food.

So removing the contaminant particles is often not enough, and more drastic and expensive interventions are required, such as the destruction of whole foodstuffs and supplies.

The basic problem is that the detection of very small particles of synthetic resins is not possible using conventional methods such as metal detectors. In fact, polymers cannot be detected by means of these monitoring techniques if not appropriately modified.

The recent withdrawal campaigns of well known companies, were imposed by the presence of plastic pieces inside the product intended for consumption.

To solve this type of problems, LATI has introduced to the market its range of compounds that can be detected by any instrument for the insulation from metallic contamination.

The family of MDT thermoplastic products is, in fact, formulated starting from conventional plastic materials reinforced with special ceramic powders able to change the magnetic field of detectors. In this way, even the smallest contamination from plastic particles can be immediately detected, making the entire production cycle safe. MDT compounds have been developed for injection molding, but can also be engineered for other types of processing, e.g. calendering or extrusion.

For this reason, they are suitable for the manufacture of any product, from boxes to containers, from locking systems to any kind of transport line. Temperature and working environment do not represent a limit for MDT compounds, since LATI’s portfolio includes materials suitable for both extreme temperatures (PEEK and PPS) and chemical etching (PP and PA).

The presence of sudden mechanical stresses arising from the use of these products was also considered, and there will be no disappointment with MDT materials as regards strength and toughness.

In fact, compounds made of impact-resistant polypropylene or elastomer are available, which are also excellent for products subject to impacts and vibrations. All MDT compounds are, of course, suitable for contact with food and fully compliant with the most stringent European and worldwide toxicological safety standards.

The replacement of a part made of generic plastics with an MDT compound may occur with marginal cost incidence, but it definitively prevents potentially catastrophic accidents.

LATI’s engineers are always at customers’ disposal to discuss specifications and plans, for defining set-up of design and manufacture, and for the assessment of costs and benefits.