Safer Food Conveyor Belts Thanks to Detectable Compounds

Metal detectable technical polymers for food processing: traceability and safety become standard in food contact plastic materials. The GANAL case study.

LATI Obtains OCS Certification: the Value of those who Prevent Pellet Loss Every Day

Training, KPIs, and Audits to Integrate Certifications into Business Processes

LATI Obtains ISO 50001 Certification: a New Milestone for Energy Sustainability

LATI has reached an important milestone: obtaining the ISO 50001:2018 certification, the international standard for energy management.

Lead-free Brass and Structural Compounds: Innovative Materials for a Safer Future

European regulations and growing public health concerns are accelerating the elimination of leaded brass, driving the industry toward alternative and innovative materials such as ecological alloys and structural thermoplastic compounds.

CEJN Chooses LATI Detectable Compounds: Stop Contamination!

Discover why CEJN has selected LATI’s detectable thermoplastic materials for the production of the new 208 Detect blow gun

Reliable Detectable Plastic Materials for Demanding Food Production Environments

In the highly regulated and demanding food sector, safety, durability, and hygiene are essential

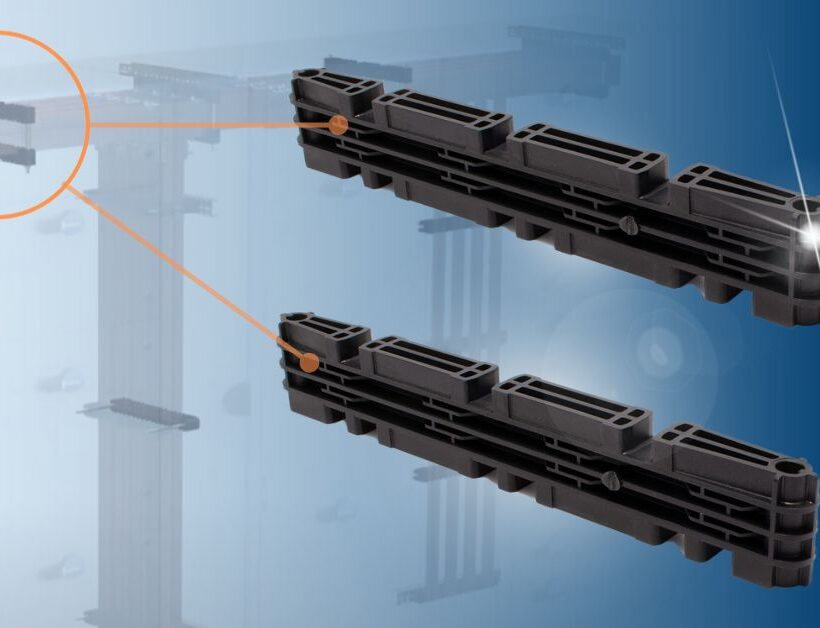

Self-extinguishing Materials for Electrical Energy Transport

The rapid development of high voltage and current applications requires new plastic materials resistant to operating conditions.

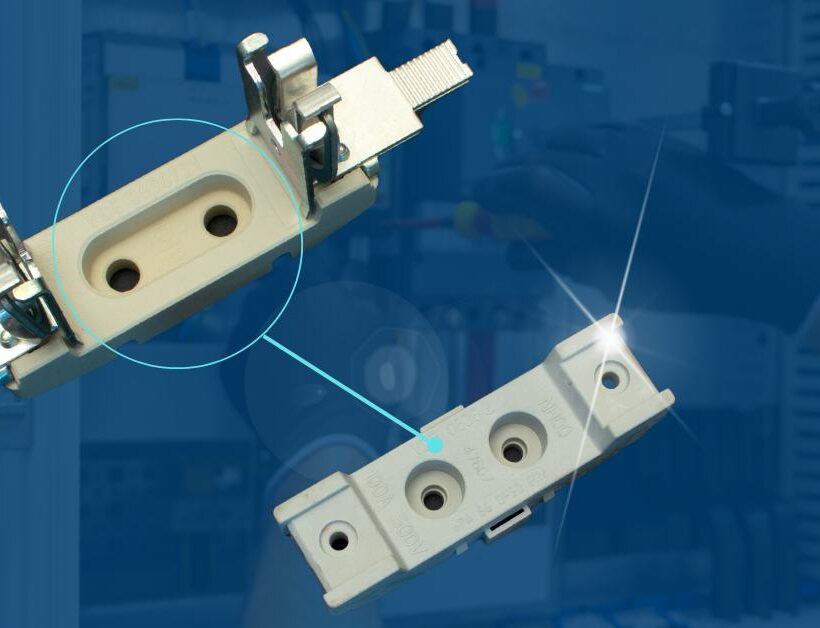

Plastic Materials for Distributing Electricity Safely and Sustainably – the EFEN Case

Discover how EFEN, a leading German company in the production of electrotechnical devices, decided to replace the ceramics used in its NG series fuse holders and switches with the LATI flame-retardant thermoplastic compound, LATAMID 66

Digital and Energy Efficiency: all LATI Aspects of Sustainable Production

Discover LATI Thermoplastic Industry’s journey towards energy efficiency. Register for the webinar!

Webinar – Detectable Materials for Safety Applications. Detectable Compounds

Detectable compounds for magnetic metal detectors or X-rays. How do they work? How are they used? What guarantees do they provide?

BTSR and LATI: a Twenty-Year Journey of Innovation and Shared Values

BTSR, whose name stands for Best Technology Study Research, develops advanced technological solutions for yarn tension control in highly automated industrial processes, primarily in the textile sector