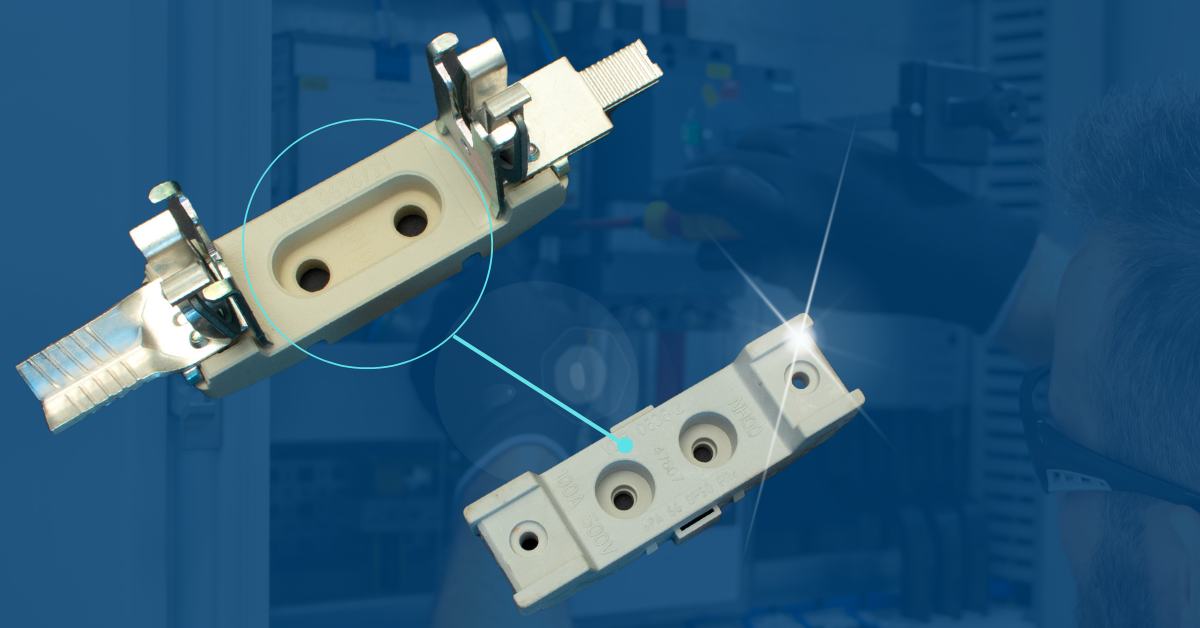

Discover how EFEN, a leading German company in the production of electrotechnical devices, decided to replace the ceramics used in its NG series fuse holders and switches with the LATI flame-retardant thermoplastic compound, LATAMID 66 H2 G/50-V0HF1.

Ceramics: the Preferred Solution for Insulators

Ceramics were the first material used to insulate applications intended for direct contact with electrical current. Over the years, porcelain insulators have been replaced in many situations by thermosetting plastic materials, such as Bakelite, and more recently, these have often given way to flame-retardant thermoplastic polymers.

The extremely high dielectric strength, thermal and chemical resistance, and timeless durability are unmatched strengths of ceramics, which are still used today in the production of medium and high voltage insulators.

The Challenge of Efen Gmbh: Replacing Ceramics with LATI Flame-Retardant Plastic

Efen Gmbh is a leading German company in the production of electrotechnical devices used in the management and distribution of electrical energy at both industrial and domestic levels. Even at Efen, porcelain insulators are present within fuse holders, switches, and dividers.However, the great intrinsic safety of these ceramic elements must contend with some inevitable disadvantages related to the material itself: the difficulty in installation and assembly, the fragility that makes screwing and fastening operations problematic, and finally, the weight and cost.Efen has taken on the challenge of replacing ceramics in its NH series fuse holders and switches by introducing a LATI flame-retardant thermoplastic compound, LATAMID 66 H2 G/50-V0HF1. Certainly a project with many uncertainties, all brilliantly addressed and overcome thanks to the performance of the plastic material consisting of a PA66 matrix reinforced with 50% glass fiber and made flame-resistant through a modern low environmental impact additive system, free of halogens and red phosphorus.

LATAMID 66 H2 G/50-V0hf1: High Performance and Sustainability

LATAMID 66 H2 G/50-V0HF1 offers unparalleled mechanical strength among flame-retardant plastic products, thanks not only to nearly 200 MPa of tensile strength but also to exceptional values of elongation at break, resilience, and elastic modulus. Its excellent resistance to tracking currents is demonstrated by a CTI of 600V, making it safe for use even in the presence of significant voltages.

The material’s fire resistance is crucial, certified by a UL94 V0 rating down to 0.4 mm: a very low thickness considering the composition of the compound itself.

The validity of LATI’s proposal is further confirmed by the widespread use of this product in equally demanding application contexts, such as the railway sector, where low emission and smoke toxicity in case of fire are imperative.

It is also interesting to note how LATAMID 66 H2 G/50-V0HF1 represents a sustainable alternative to ceramics, thanks to less energy-intensive production and processing and the substantial absence of non-recoverable waste.

The quality of LATI’s flame-retardant product range has been further consulted by EFEN, and LATAMID 66 H2 G/25-V0HF1, a less reinforced version of the compound described above, has been chosen to create the mechanical elements of the switch button mounted on vertical NH fuse holders.

Efen and LATI together demonstrate how reliability and durability of technical solutions can be ensured while increasingly focusing on performance and sustainability.