Many industrial projects traditionally use thermoset resins for their high thermal stability, rigidity, and fire behavior. However, the emergence of high-performance thermoplastics has opened new scenarios for replacing thermosets with thermoplastic materials (metal replacement, thermoset replacement). In this article, we explore the advantages, challenges, and best strategies to achieve this transition consciously.

Why Thermosets are Preferred: Strengths

Before considering replacement, it’s important to understand the strengths that make thermoset resins attractive:

- Thermal stability and softening resistance: cross-linked resins do not soften before degradation due to permanent chemical bonds.

- Low creep: cross-linking limits molecular flow, ensuring minimal deformation over time under constant load.

- Fire, electrical, and chemical behavior: thermosets often generate minimal dripping, are self-extinguishing, and feature good insulating properties.

- Dimensional stability: very low shrinkage (typically < 0.1%) even in reinforced materials, facilitating tight tolerances.

These characteristics make them suitable for critical applications such as electronics, railway, and special structural materials.

Inherent Limitations of Thermosets and Reasons for Replacement

Despite the advantages, thermosets have significant constraints:

- Irreversible process: cross-linking occurs with catalysts and controlled conditions and is irreversible. The product cannot be reshaped or recycled.

- Cure times (cycle): cross-linking requires time, temperature, and pressure, extending production cycles.

- Chemical management and safety: catalyst components can be toxic; careful management is required.

- Recycling and disposal difficulties: defective or end-of-life parts cannot be reprocessed and must be destroyed or chemically degraded.

- Design rigidity: they don’t allow reprocessing or post-cure modification, limiting design flexibility.

These critical issues are often incompatible with demands for sustainability, production flexibility, and circular economy.

Advantages and Conditions for Replacement with High-Performance Thermoplastics

Expected Characteristics from Replacement Thermoplastics

To compete with thermosets, thermoplastics must be formulated with:

- High mechanical strength and modulus: to support structural loads

- Thermal stability: often operating above 150°C

- Low moisture absorption: to maintain performance

- Chemical, electrical, and fire resistance: for technical applications

- Flame compatibility and regulations (self-extinguishing, CTI, GWIT/GWFI, smoke)

- Recyclability and reconversion potential: intrinsic characteristic of thermoplastics

Technical Strategies to Bridge the Gaps

- Load with reinforcing fibers (glass, carbon) up to 65% to increase modulus and reduce deformation

- Use functional fillers to improve heat resistance and electrical properties

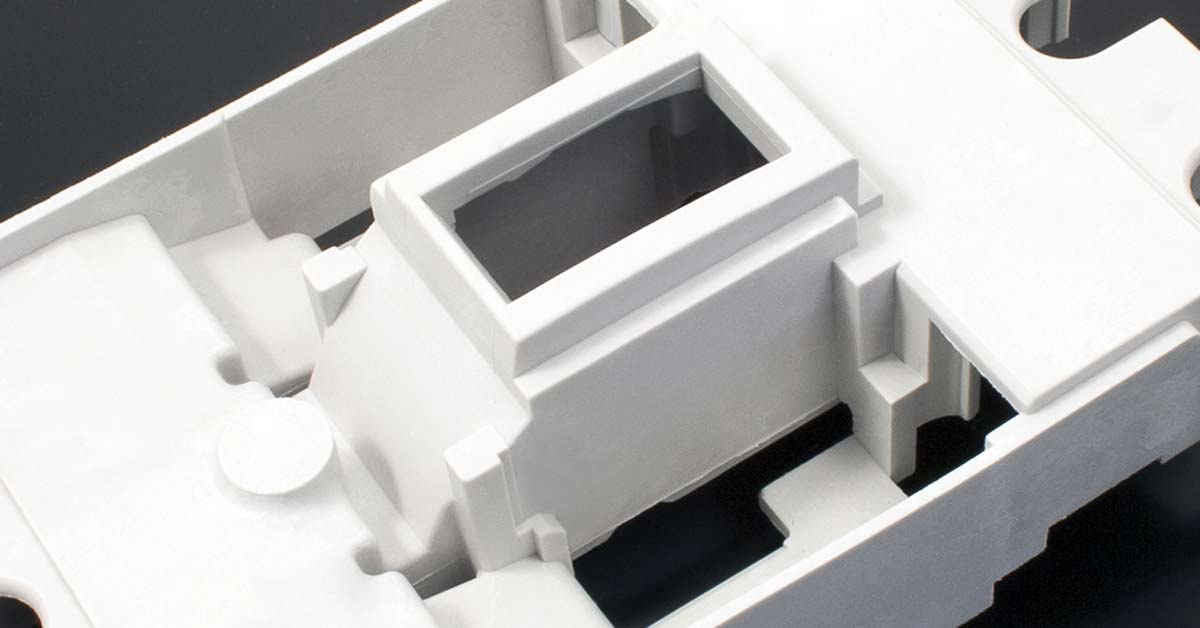

- Design optimized geometries (ribs, variable thicknesses) to compensate for lower modulus

- Simulate with FEM models that consider the anisotropy inherent in composite materials

- Validate with mechanical, thermal, and fatigue tests on the final component

Application Example and Comparative Data

LATI offers a range of thermoplastics designed for thermoset replacement, capable of operating above 150°C and under constant stress, combining fiber (up to 65%) and functional fillers. Some materials are also made self-extinguishing, compliant with standards such as IEC 60335 (GWIT/GWFI), CTI, and with reduced smoke emissions.

A table summarizes the differences between traditional thermosets and advanced thermoplastics:

| Aspect | Classic Thermosets | High-Performance Thermoplastics |

| Process | Irreversible cure, long times | Molding, quick times, recyclable |

| Deformation over time | Minimal due to cross-linking | Controlled through reinforcements and design |

| Recycling / disposal | Not reprocessable | Reprocessable and recyclable |

| Thermal performance | High until degradation | Good up to > 150°C, with additives |

| Design freedom | Limited post-cure | Greater freedom in shape and modifications |

| Process costs | High for management, curing, waste | Potentially lower at large scale |

Final Considerations and Invitation for further Exploration

The transition from thermosets to high-performance thermoplastics is neither automatic nor universal, but a technical journey requiring material understanding, sophisticated design, and operational constraint analysis. If the context allows — moderate environments, recycling requirements, high volumes — advanced thermoplastics can offer advantages in terms of flexibility, economy, and sustainability.

If you wish, we can help you evaluate the potential crossover for your specific project, compare LATI grades with existing thermosets, and estimate costs and performance. Contact us to learn more.

FAQ

Q1: When is it advantageous to replace a thermoset with a high-performance thermoplastic?

When the required performance falls within thermoplastic limits (e.g., temperatures < 200°C), and gains in recyclability, costs, and design flexibility are desired.

Q2: What is the typical thermal limit for advanced thermoplastics?

They can operate above 150°C, in some formulations up to 200-220°C, while maintaining good mechanical properties.

Q3: What main challenges should I expect in the replacement process?

The main challenges are: adapting geometry to the material, managing reinforcement-induced anisotropy, ensuring dimensional stability, and validating the material with cyclic testing.