Innovation in Materials for Railway Transport

In the modern railway sector, the evolution of materials used in the construction of structural and safety components is a determining factor to ensure high mechanical performance, fire resistance and environmental sustainability.

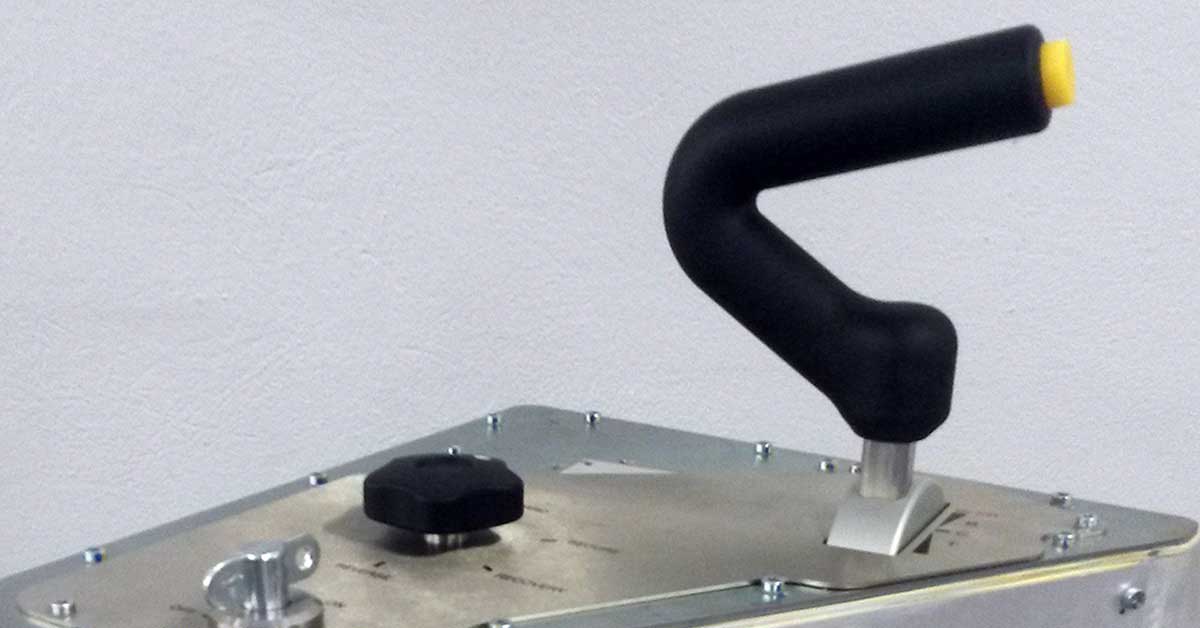

A concrete example comes from the collaboration between SPII S.p.A., an Italian company leader in the design of control desks and driving stations, and LATI Industria Termoplastici S.p.A., specialist in structural and self-extinguishing thermoplastic compounds for advanced applications.

From Thermosetting Resins to Structural Thermoplastic Compounds

For many years, thermosetting resins such as BMC or phenolic have been used in structural railway components, known for their rigidity but limited in terms of recyclability and processability.

SPII decided to innovate by introducing structural and self-extinguishing thermoplastic compounds, capable of matching – and in many cases exceeding – the mechanical performance of thermosets, while offering lightness, durability and sustainability.

The material selected for the new control handles is LATAMID 66 H2 G/50-V0HF1, a PA66-based compound reinforced with 50% glass fiber and halogen-free self-extinguishing, designed to reduce environmental impact and ensure maximum safety.

Mechanical Performance and Fire Safety

The LATAMID 66 H2 G/50-V0HF1 compound was subjected to a FEM (Finite Element Method) validation process to simulate real-use conditions, verifying structural robustness, tightening resistance and internal stress distribution.

After passing the tests, SPII started production of handles capable of withstanding vertical forces up to 1000 N applied to the horizontal arm of the lever, without failure or deformation.

In addition to mechanical resistance (≈ 200 MPa at break), the material ensures high self-extinguishing properties, with UL94-V0 classification even on reduced thicknesses down to 0.4 mm.

Furthermore, it presents a glow wire flammability index (GWFI) of 960°C according to IEC 60695-2-12, an essential parameter to ensure safety in railway devices subject to heat or electrical sparks.

Long-term Reliability and Sustainability

Thanks to dimensional stability and the relative temperature index (RTI UL 746-B) of 130°C, the compound maintains its mechanical, electrical and flame resistance characteristics over time, even after prolonged thermal cycles.

An additional advantage is the recyclability of the component at end of life, an aspect that is now a priority for the European railway sector, which aims to reduce the overall environmental impact of fleets.

Main Technical Data of LATAMID 66 H2 G/50-V0hf1 Compound

| Property | Typical value | Reference standard |

| Polymer base | PA66 reinforced 50% glass fiber | – |

| Tensile strength | ≈ 200 MPa | ISO 527 |

| Self-extinguishing | UL94-V0 (up to 0.4 mm) | UL94 |

| GWFI (Glow Wire Flammability Index) | 960°C | IEC 60695-2-12 |

| RTI (UL 746-B) | 130°C | UL |

| Flame retardant additives | Halogen-free | – |

| Recyclability | High | – |

Applications and Benefits for the Railway Sector

The

- Control levers and handles for control desks.

- Internal structural components of railway cabins.

- Technical metal replacement elements, with weight reduction up to 40%.

- Parts subject to continuous thermal and mechanical stress.

LATI and SPII demonstrate how new generation self-extinguishing technopolymers can replace traditional materials, improving production efficiency, safety and sustainability.

Conclusion

Explore LATI solutions for the railway sector: contact the technical team to evaluate the most suitable structural compound for your applications in terms of safety, performance and regulatory compliance.

FAQ – Self-extinguishing Structural Compound for Railway Applications

- What advantages does a structural compound offer compared to a thermosetting resin?

Better workability, recyclability, reduced molding times and greater long-term dimensional stability. - What does UL94-V0 classification mean?

It indicates that the material is self-extinguishing, stops the flame within 10 seconds and does not release incandescent drops, even on minimum thicknesses. - Why is GWFI 960°C important in railway components?

It ensures resistance to contact with incandescent parts, preventing fire ignition in electrical and control systems.